2021 Good Quality Precision Glass Solutions - Precision Metal Machining – ZHONGHUI

2021 Good Quality Precision Glass Solutions - Precision Metal Machining – ZHONGHUI Detail:

The machines that are most commonly used range from mills, lathes to a wide variety of cutting machines. One characteristic of the different machines used during the modern metal machining is the fact that their movement and operation is controlled by computers which use CNC (computer numerical control), a method that is of crucial importance for achieving precise results.

The machines that are most commonly used range from mills, lathes to a wide variety of cutting machines. One characteristic of the different machines used during the modern metal machining is the fact that their movement and operation is controlled by computers which use CNC (computer numerical control), a method that is of crucial importance for achieving precise results.

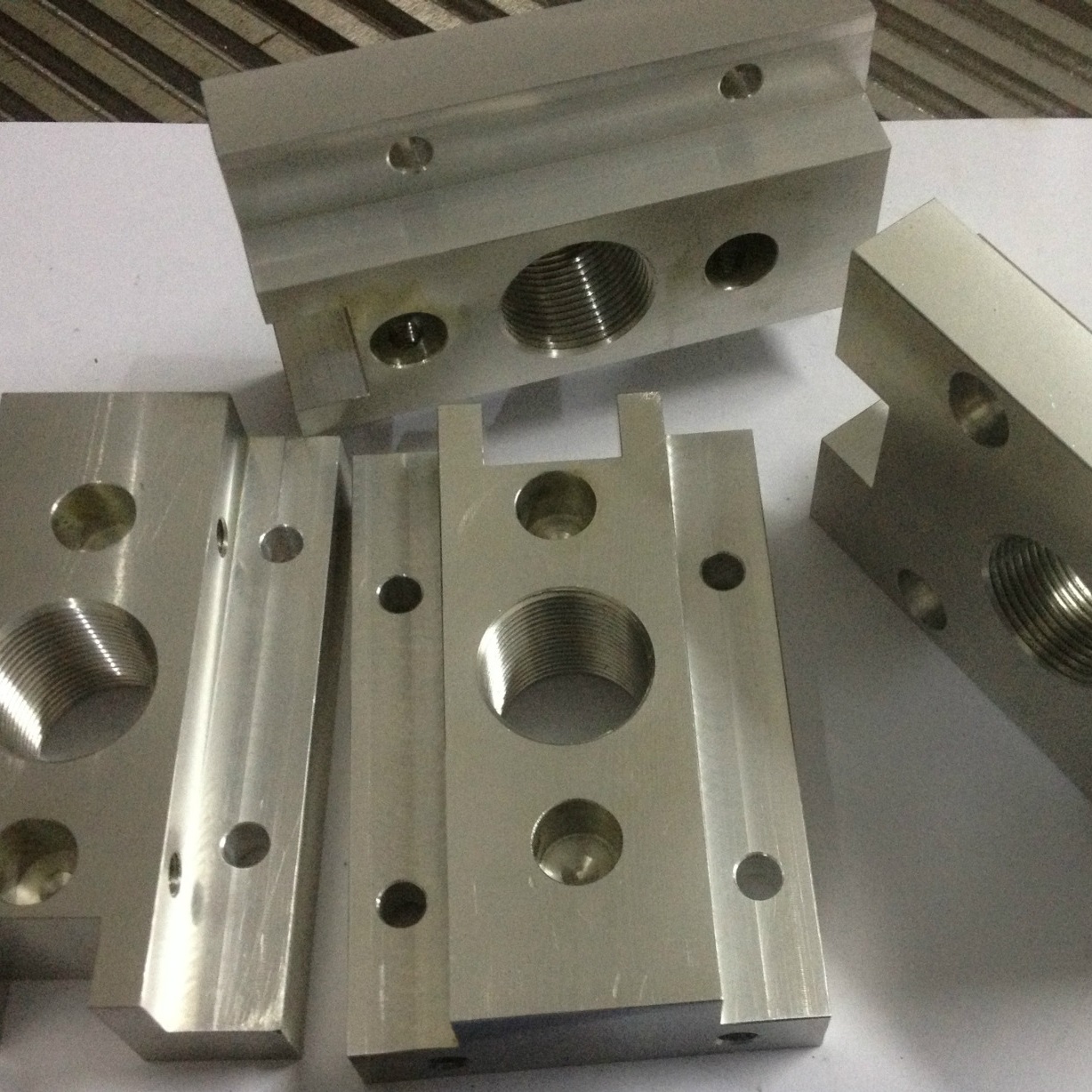

TYPES OF METAL MACHINING OPERATIONS

The most commonly performed and one of the most important machining operations are:

● Turning – This operation is performed on a material which is rotating while a tool is removing material from it. The main purpose of turning operations is receiving cylindrical shape of the material being processed.

● Drilling – It’s an operation during which a rotating tool is used for making a round hole on the surface of the material. The rotating that is used (usually drill bit) has two cutting edges that have the main function of making the round hole.

● Milling – There are two types of milling: peripheral and face milling. Although performed with different method and tools, the main purpose of both forms of milling operations have one main purpose – to create plain and straight surface.

|

Model |

Details |

Model |

Details |

|

Size |

Custom |

Application |

CNC, Laser, CMM… |

|

Condition |

New |

After-sales Service |

Online supports, Onsite supports |

|

Origin |

Jinan City |

Material |

Stainless steel, copper, aluminum, iron, cast iron. . . |

|

Color |

Metal Original Color |

Brand |

ZHHIMG |

|

Precision |

0.001mm |

Weight |

≈7g/cm3 |

|

Standard |

DIN/ GB/ JIS… |

Warranty |

1year |

|

Packing |

Export Plywood CASE |

After Warranty Service |

Video technical support, Online support, Spare parts, … |

|

Payment |

T/T, L/C… |

Certificates |

Inspection Reports/ Quality Certificate |

|

Keyword |

Ceramic Machine Base; Ceramic Mechanical Components; Ceramic Machine Parts; Precision Ceramic |

Certification |

CE, GS, ISO, SGS, TUV… |

|

Delivery |

EXW; FOB; CIF; CFR; DDU; CPT… |

Drawings’ format |

CAD; STEP; PDF… |

WHY IS METAL MACHINING IMPORTANT

● Is suitable for processing wide variety of materials;

● Enables creating wide range of geometric shapes such as accurate round holes, screw threads, straight edges, as well as surfaces;

● Provides very good dimensional accuracy and plane and straight surface finish;

● Metal machining enables high precision during the creation of the desired final shape, dimension, size and surface finish.

● This procedure provides results with geometric specifications which cannot be created by other processes.

● This type of machining can be used in many manufacturing processes during operations such as casting, bar drawing and forging.

1. Documents together with products: Inspection reports + Calibration reports(measuring devices) + Quality Certificate + Invoice + Packing List + Contract + Bill of Lading(or AWB).

2. Special Export Plywood Case: Export fumigation-free wooden box.

3. Delivery:

|

Ship |

Qingdao port |

Shenzhen port |

TianJin port |

Shanghai port |

… |

|

Train |

XiAn Station |

Zhengzhou Station |

Qingdao |

… |

|

|

Air |

Qingdao Airport |

Beijing Airport |

Shanghai Airport |

Guangzhou |

… |

|

Express |

DHL |

TNT |

Fedex |

UPS |

… |

1. We will offer technical supports for assembly, adjustment, maintain.

2. Offering the manufacturing &inspection videos from selecting material to delivery, and customers can control and know every detail at anytime anywhere.

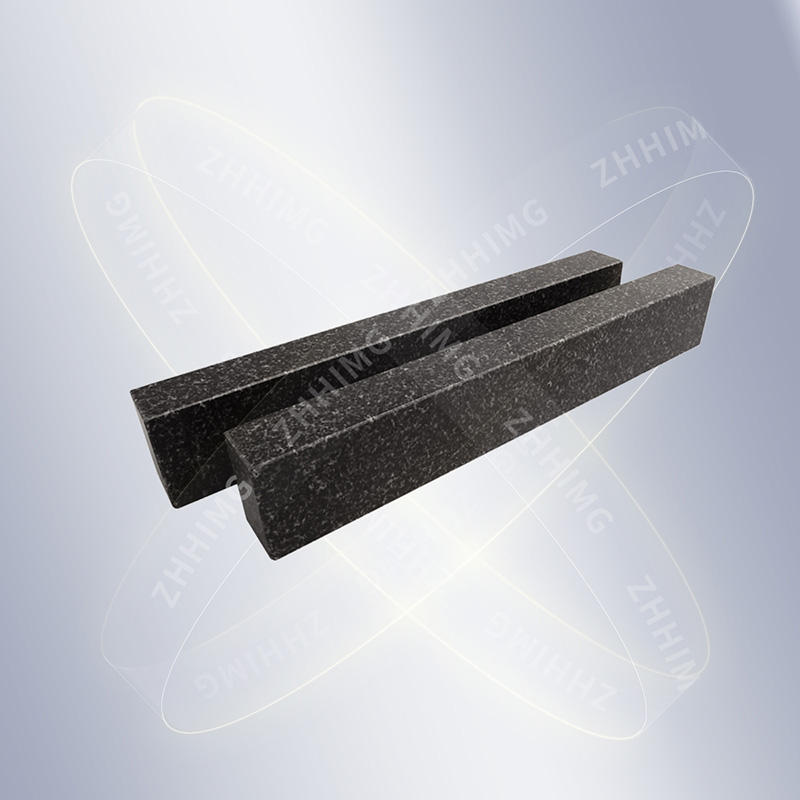

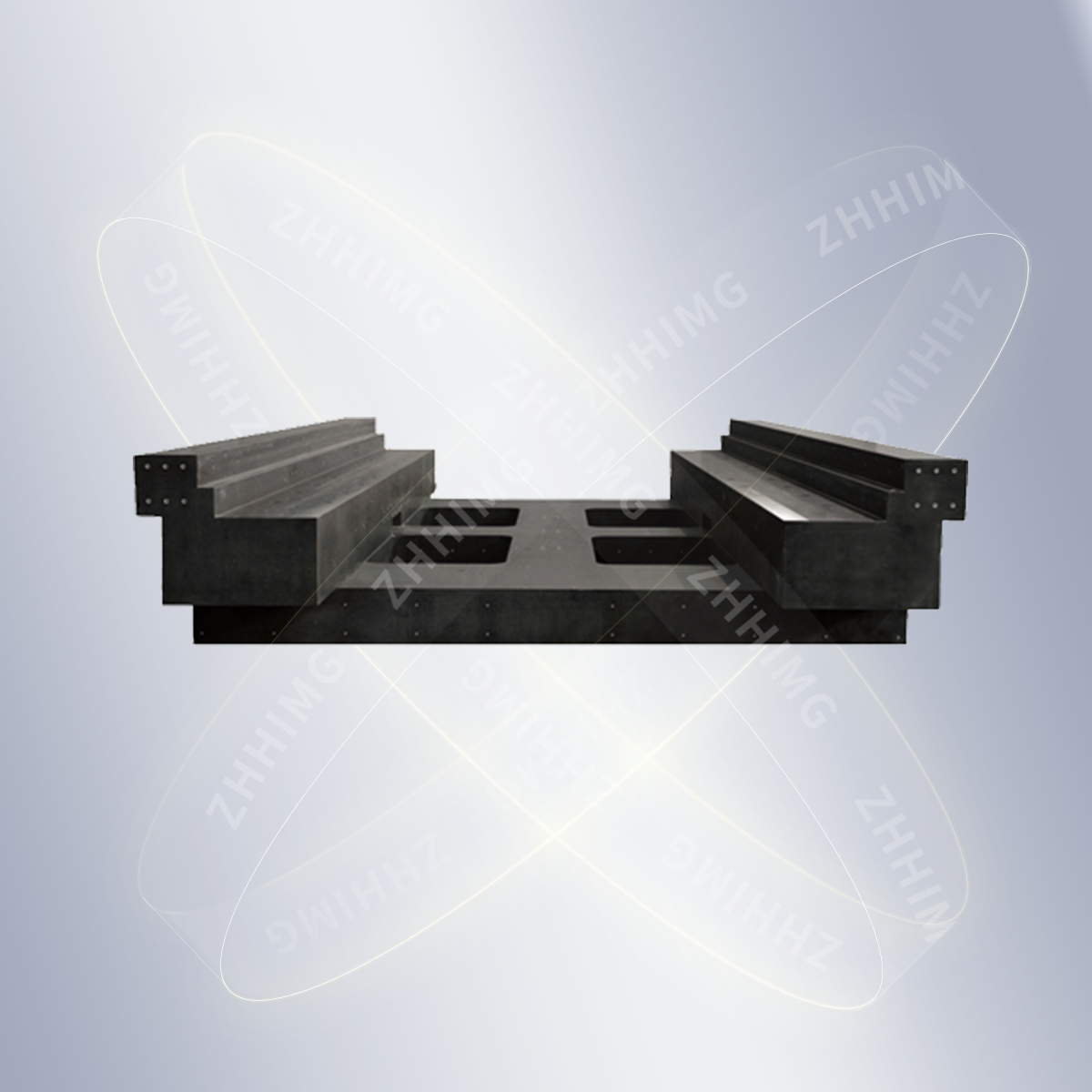

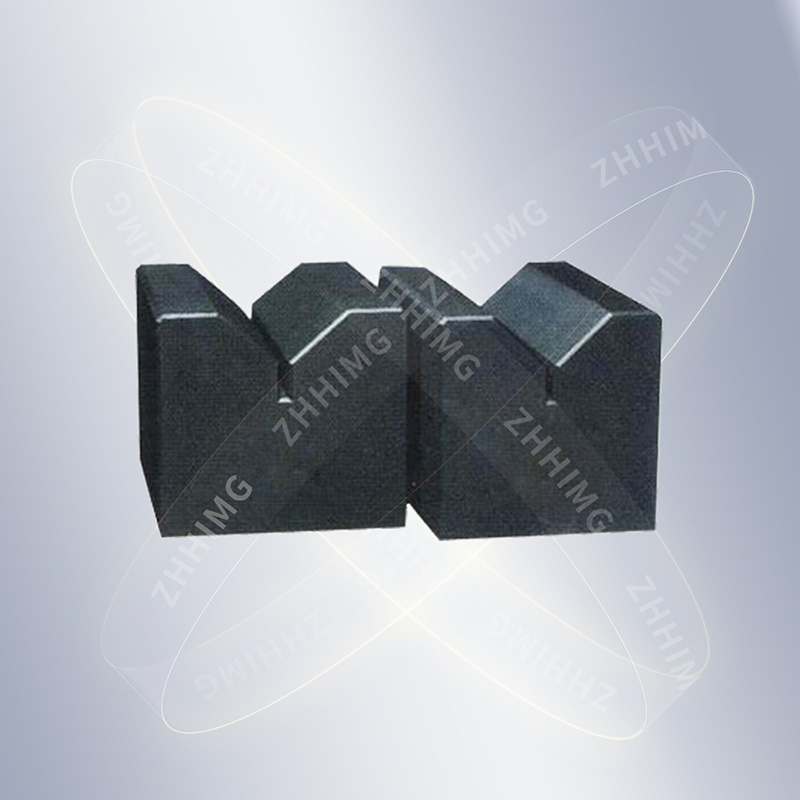

Product detail pictures:

Related Product Guide:

Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for 2021 Good Quality Precision Glass Solutions - Precision Metal Machining – ZHONGHUI , The product will supply to all over the world, such as: Ottawa, Macedonia, Stuttgart, As a way to make use of the resource on the expanding information and facts in international trade, we welcome prospects from everywhere on the web and offline. In spite in the top quality products and solutions we supply, effective and satisfying consultation service is supplied by our professional after-sale service group. Solution lists and thorough parameters and any other info weil be sent for you timely for the inquiries. So make sure you get in touch with us by sending us emails or contact us if you have any concerns about our firm. ou can also get our address info from our web site and come to our enterprise. or a field survey of our solutions. We're confident that we have been going to share mutual results and build solid co-operation relations with our companions in this market. We're looking forward to your inquiries.

QUALITY CONTROL

If you can’t measure something, you can’t understand it!

If you can’t understand it.you cant control it!

If you can’t control it, you can’t improve it!

More information please click here: ZHONGHUI QC

ZhongHui IM, your partner of metrology, help you succeed easily.

Our Certificates & Patents:

Certificates and Patents are an expression of a company’s strength. It’s society’s recognition of the company.

More certificates please click here: Innovation & Technologies – ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (zhhimg.com)

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!