Factory source Non Destructive Testing Granite Base - Precision Granite Parallels – ZHONGHUI

Factory source Non Destructive Testing Granite Base - Precision Granite Parallels – ZHONGHUI Detail:

All Granite Rulers are tested in a temperature (20°C) and humidity controlled environment.

All ZHHIMG® plates are supplied with a Test Report, in which error map and installation instructions are reported.

Calibration Certificate available on request*.

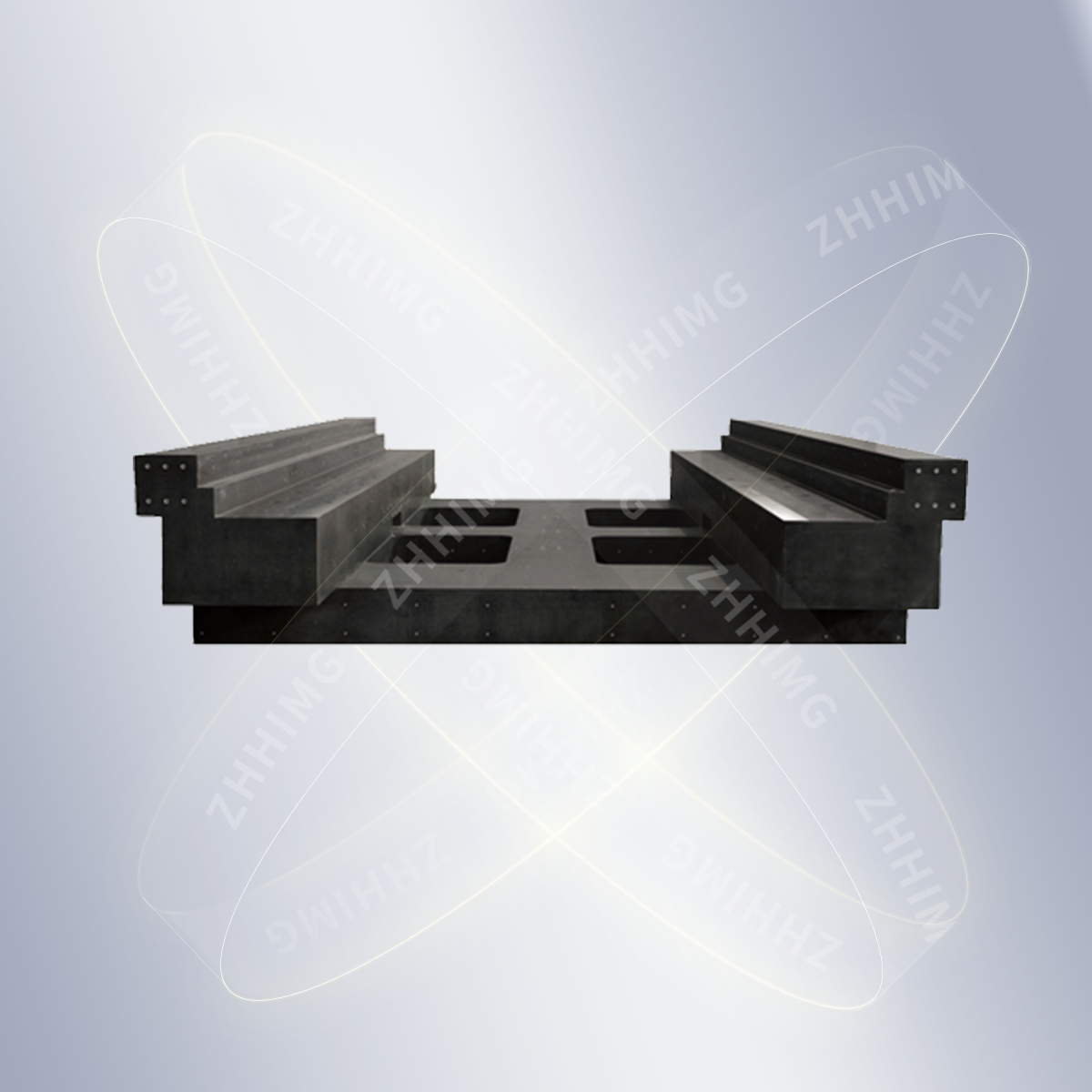

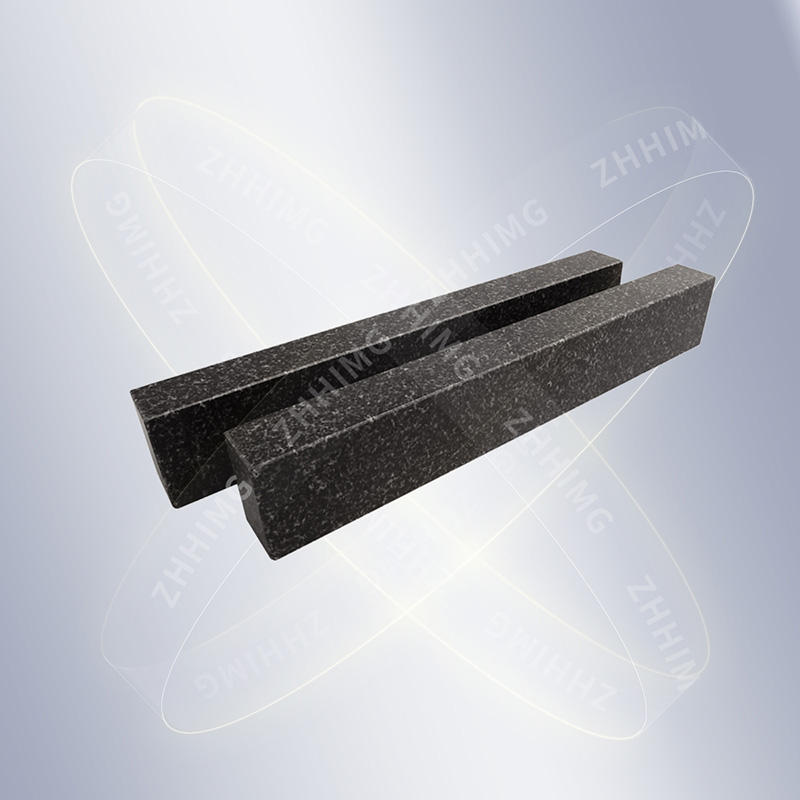

Produced in four standard sizes, Granite Parallels are useful in setting up work on surface plates and machine tables. They can also be used to elevate work above the surface of a plate to enable quick and easy inspection of piece parts with shoulders or steps. Available in matched pairs, finished flat and parallel on two opposite narrow faces or all four faces. Parallels are sold in matched pairs. Single parallels available by request. Storage cases are available at extra cost.

The chart shows standard sizes, weights, article codes and the absolute flatness tolerances (in micrometers).

ZHHIMG® can supply granite parallels with different sizes according to customer needs and drawings, with holes, threaded inserts, guide or clamping T-slots, clearing grooves and with rubber feet (for the smaller sizes).

|

TYPE (mm) |

flatness of working surface and parallelism between opposite surfaces |

squareness between working surfaces |

length and width differences between a matched pair |

|||

|

Precision Grade(μm) |

||||||

|

00 |

0 |

00 |

0 |

00 |

0 |

|

|

160*25*16 |

1.5 |

3 |

20 |

40 |

1.5 |

3 |

|

250*40*25 |

2 |

4 |

30 |

60 |

2 |

4 |

|

400*63*40 |

4 |

8 |

40 |

80 |

4 |

8 |

|

450*75*40 |

4.5 |

9 |

45 |

90 |

4.5 |

9 |

|

630*100*63 |

6 |

12 |

50 |

100 |

6 |

12 |

|

Please ask if need custom granite parallels. |

||||||

|

Model |

Details |

Model |

Details |

|

Size |

Custom |

Application |

Metrology, Measuring,Calibration... |

|

Condition |

New |

After-sales Service |

Online supports, Onsite supports |

|

Origin |

Jinan City |

Material |

Black Granite |

|

Color |

Black / Grade 1 |

Brand |

ZHHIMG |

|

Precision |

0.001mm |

Weight |

≈3.05g/cm3 |

|

Standard |

DIN/ GB/ JIS... |

Warranty |

1year |

|

Packing |

Export Plywood CASE |

After Warranty Service |

Video technical support, Online support, Spare parts, Field mai |

|

Payment |

T/T, L/C... |

Certificates |

Inspection Reports/ Quality Certificate |

|

Keyword |

Granite Measuring Table; Granite Inspection Plate, Precision Granite Surface Plate |

Certification |

CE, GS, ISO, SGS, TUV... |

Granite is a type of igneous rock quarried for its extreme strength, density, durability, and resistance to corrosion. Ultra Precision Manufacturing Department at ZHHIMG confidently works with granite components engineered in shapes, angles, and curves of all variations on a regular basis—with excellent outcomes.

Through our state of the art processing, cut surfaces can be exceptionally flat. These qualities make granite the ideal material to create custom-size and custom-design machine bases and metrology components.

Our Superior Black Granite has low water absorption rates, minimizing the possibility of your precision gages rusting while setting on the plates.

When your application calls for a plate with custom shapes, threaded inserts, slots or other machining. This natural material offers superior stiffness, excellent vibration dampening, and improved machinability.

Due to its unique properties, black granite in recent years, has been used extensively in the field of measuring instruments, both for traditional ones (surface plates, parallels, set squares, etc…), as well as modern ones: CMM machines, physic-chemical process machine tools.

Due to its unique properties, black granite in recent years, has been used extensively in the field of measuring instruments, both for traditional ones (surface plates, parallels, set squares, etc…), as well as modern ones: CMM machines, physic-chemical process machine tools.

Suitably lapped black granite surfaces are not only extremely precise but also ideal for use in conjunction with air bearings.

The reason of the choice of black granite in manufacturing of precision units are the following:

DIMENSIONAL STABILITY: black granite is a natural aged material formed over millions of years and therefore displays great internal stability

THERMAL STABILITY: the linear expansion is much lower than the steel or cast iron ones

HARDNESS: comparable to good-quality tempered steel

WEAR RESISTANCE: instruments last longer

ACCURACY: the flatness of the surfaces is better than the one obtained with traditional materials

RESISTANCE TO ACIDS, NON-MAGNETIC ELECTRICAL INSULATION RESISTANCE TO OXIDATION: no corrosion, no maintenance

COST: working the granite with state-of-the-art technology prices are lower

OVERHAUL: Eventual servicing can be carried out quickly and cheaply

1.Docments together with products: Inspection reports + Calibration reports(measuring devices) + Quality Certificate + Invoice + Packing List + Contract + Bill of Lading(AWB)

2.Special Export Plywood Case: Special Aluminium Case + Custom Export fumigation-free wooden box

3. Delivery:

|

Ship |

Qingdao port |

Shenzhen port |

TianJin port |

Shanghai port |

... |

|

Train |

XiAn Station |

Zhengzhou Station |

Qingdao |

... |

|

|

Air |

Qingdao Airport |

Beijing Airport |

Shanghai Airport |

Guangzhou |

... |

|

Express |

DHL |

TNT |

Fedex |

UPS |

... |

1. We will offer technical supports for assembly, adjustment, maintain.

2. Offering the manufacturing &inspection videos, and customers can control and konw every detail at anytime anywhere.

Product detail pictures:

Related Product Guide:

We take "customer-friendly, quality-oriented, integrative, innovative" as objectives. "Truth and honesty" is our administration ideal for Factory source Non Destructive Testing Granite Base - Precision Granite Parallels – ZHONGHUI , The product will supply to all over the world, such as: Ecuador, Tunisia, Angola, Our factory is equipped with complete facility in 10000 square meters, which makes us be able to satisfy the producing and sales for most auto part products. Our advantage is full category, high quality and competitive price! Based on that, our products win a high admiration both at home and abroad.

QUALITY CONTROL

If you can’t measure something, you can’t understand it!

If you can’t understand it.you cant control it!

If you can’t control it, you can’t improve it!

More information please click here: ZHONGHUI QC

ZhongHui IM, your partner of metrology, help you succeed easily.

Our Certificates & Patents:

Certificates and Patents are an expression of a company’s strength. It’s society’s recognition of the company.

More certificates please click here: Innovation & Technologies – ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (zhhimg.com)

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.