Granite is a type of igneous rock quarried for its extreme strength, density, durability, and resistance to corrosion. But granite is also very versatile– it’s not just for squares and rectangles! In fact, We confidently work with granite components engineered in shapes, angles, and curves of all variations on a regular basis—with excellent outcomes.

Through our state of the art processing, cut surfaces can be exceptionally flat. These qualities make granite the ideal material to create custom-size and custom-design machine bases and metrology components. Granite is:

■ machinable

■ precisely flat when cut and finished

■ rust resistant

■ durable

■ long lasting

Granite components are also easy to clean. When creating custom designs, be sure to choose granite for its superior benefits.

STANDARDS / HIGH WEAR APPLICATIONS

The granite utilized by ZHHIMG for our standard surface plate products has high quartz content, which provides greater resistance to wear and damage. Our Superior Black colors have low water absorption rates, minimizing the possibility of your precision gauges rusting while setting on the plates. The colors of granite offered by ZHHIMG result in less glare, which means less eyestrain for individuals using the plates. We have chosen our granite types while considering thermal expansion in an effort to keep this aspect minimal.

CUSTOM APPLICATIONS

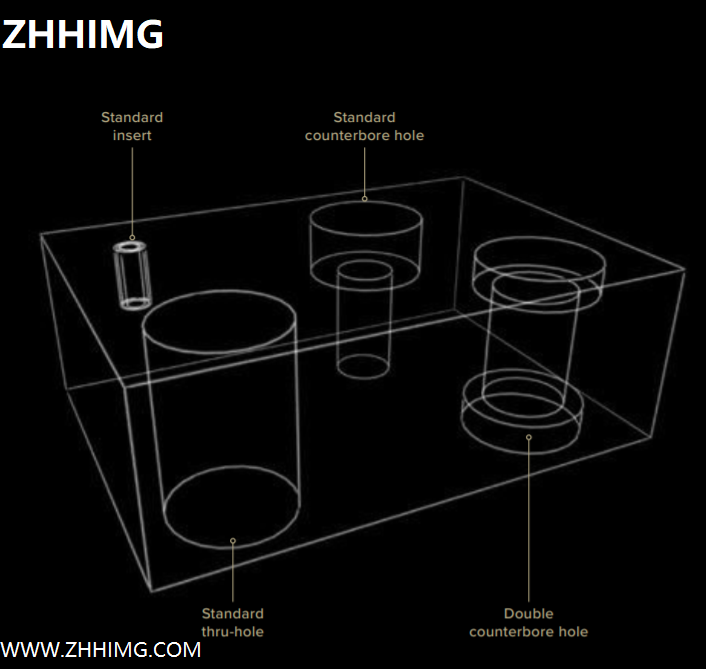

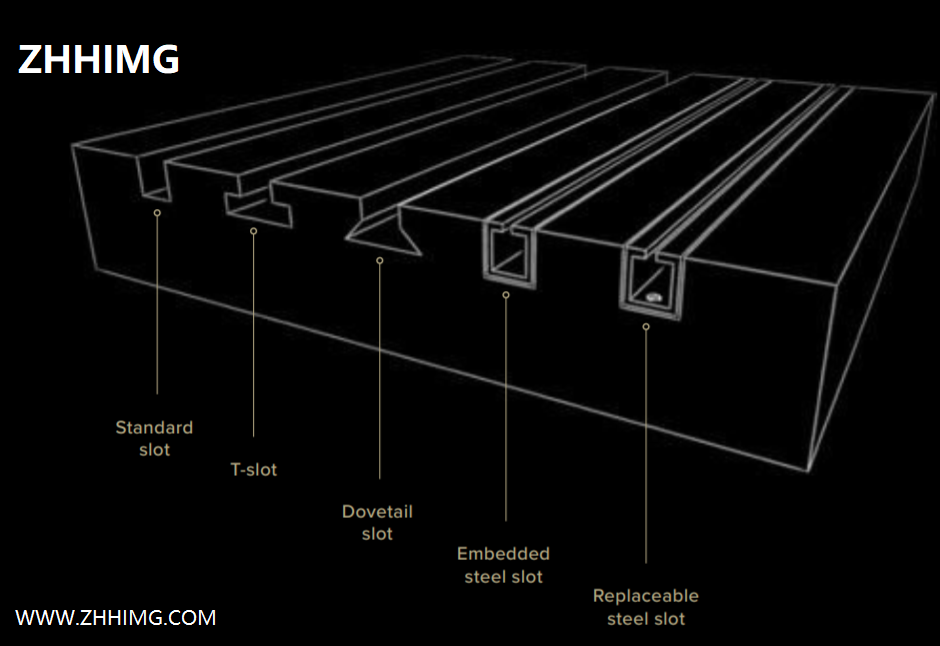

When your application calls for a plate with custom shapes, threaded inserts, slots or other machining, you’ll want to select a material like Black Jinan Black. This natural material offers superior stiffness, excellent vibration dampening, and improved machinability.

It is important to note that color alone is not an indication of the physical qualities of the stone. In general, granite’s color is directly related to the presence or absence of minerals, which may have no bearing on the qualities that make good surface plate material. There are pink, gray, and black granites that are excellent for surface plates, as well as black, gray, and pink granites that are totally unsuitable for precision applications. The critical characteristics of granite, as they pertain to its use as a surface plate material, have nothing to do with color, and are as follows:

■ Stiffness (deflection under load - indicated by Modulus of Elasticity)

■ Hardness

■ Density

■ Wear resistance

■ Stability

■ Porosity

We have tested many granite materials and compared these material. Finally we get the result, Jinan black granite is the best material we’ve ever know. Indian Black granite and South African granite are similar to Jinan Black Granite, but their physical properties are less than Jinan Black Granite. ZHHIMG will keep looking for more granite material in the world and compare their physical properties.

To talk more about the granite that is right for your project, please contact us info@zhhimg.com.

Different manufacturers use different standards. There are many standards in the world.

DIN Standard, ASME B89.3.7-2013 or Federal Specification GGG-P-463c (Granite Surface Plates) and so on as a basis for their specifications.

And we can manufacture granite precision inspection plate according to your requirements. Welcome to contact us if you want to know more information about more standards.

Flatness can be considered as all points on the surface being contained within two parallel planes, the base plane and the roof plane. The measurement of distance between the planes is the overall flatness of the surface. This flatness measurement commonly carries a tolerance and may include a grade designation.

For example, the flatness tolerances for three standard grades are defined in the federal specification as determined by the following formula:

■ Laboratory Grade AA = (40 + diagonal squared/25) x .000001" (unilateral)

■ Inspection Grade A = Laboratory Grade AA x 2

■ Tool Room Grade B = Laboratory Grade AA x 4.

For standard sized surface plates, we guarantee flatness tolerances that exceed the requirements of this specification. In addition to flatness, ASME B89.3.7-2013 & Federal Specification GGG-P-463c address topics including: repeat measurement accuracy, material properties of surface plate granites, surface finish, support point location, stiffness, acceptable methods of inspection, installation of threaded inserts, etc.

ZHHIMG granite surface plates and granite inspection plates meet or exceed all of the requirements set forth in this specification. At present, there is no defining specification for granite angle plates, parallels, or master squares.

And you can find the formulas for other standards in DOWNLOAD.

First, it is important to keep the plate clean. Airborne abrasive dust is usually the greatest source of wear and tear on a plate, as it tends to embed in work pieces and the contact surfaces of gages. Second, cover your plate to protect it from dust and damage. Wear life can be extended by covering the plate when not in use, by rotating the plate periodically so that a single area does not receive excessive use, and by replacing steel contact pads on gauging with carbide pads. Also, avoid setting food or soft drinks on the plate. Note that many soft drinks contain either carbonic or phosphoric acid, which can dissolve the softer minerals and leave small pits in the surface.

This depends on how the plate is being used. If possible, we recommend cleaning the plate at the beginning of the day (or work shift) and again at the end. If the plate becomes soiled, particularly with oily or sticky fluids, it should probably be cleaned immediately.

Clean the plate regularly with liquid or ZHHIMG Waterless surface plate cleaner. The choice of cleaning solutions is important. If a volatile solvent is used (acetone, lacquer thinner, alcohol, etc.) the evaporation will chill the surface, and distort it. In this case, it is necessary to allow the plate to normalize before using it or measurement errors will occur.

The amount of time required for the plate to normalize will vary with the size of the plate, and the amount of chilling. An hour should be sufficient for smaller plates. Two hours may be needed for larger plates. If a water-based cleaner is used, there will also be some evaporative chilling.

The plate will also retain the water, and this could cause rusting of metal parts in contact with the surface. Some cleaners will also leave a sticky residue after they dry, which will attract airborne dust, and actually increase wear, rather than decreasing it.

This depends on the plate usage and environment. We recommend that a new plate or precision granite accessory receive a full recalibration within one year of purchase. If the granite surface plate will see heavy use, it may be advisable to shorten this interval to six months. Monthly inspection for repeat measurement errors using a Electronic level, or similar device will show any developing wear spots and only takes a few minutes to perform. After the results of the first recalibration are determined, the calibration interval may be extended or shortened as allowed or required by your internal quality system.

We can offer service to help you inspect and calibrate your granite surface plate.

There are several possible causes for variations between calibrations:

- The surface was washed with a hot or cold solution prior to calibration, and was not allowed sufficient time to normalize

- The plate is improperly supported

- Temperature change

- Drafts

- Direct sunlight or other radiant heat on the surface of the plate. Be sure that overhead lighting is not heating the surface

- Variations in the vertical temperature gradient between winter and summer (If at all possible, know the vertical gradient temperature at the time the calibration is performed.)

- Plate not allowed sufficient time to normalize after shipment

- Improper use of inspection equipment or use of non-calibrated equipment

- Surface change resulting from wear