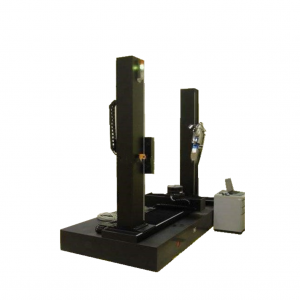

Granite Base for Picosecond laser

ZHHIMG Picosecond Laser Granite Base: The Foundation of Ultra-Precision Industry

The ZHHIMG Picosecond Laser Granite Base is engineered for ultra-precision industrial applications, combining advanced laser technology with the unparalleled stability of natural granite. Designed to support high-precision machining systems, this base delivers exceptional durability and accuracy, meeting the rigorous demands of industries such as semiconductor manufacturing, optical component production, and medical device engineering. As a trusted partner to Fortune 500 companies, ZHHIMG drives innovation in cutting-edge sectors by delivering solutions that redefine precision.

Core Technical Advantages

- Ultra-Stable Granite Material

Crafted from high-purity natural granite, the base features an ultra-low thermal expansion coefficient (≤0.8×10⁻⁶/°C) and superior vibration resistance. These properties ensure micron-level accuracy even under prolonged operation, outperforming traditional metal bases in environments with temperature fluctuations or mechanical stress. - Proprietary Structural Design

ZHHIMG’s Multi-Dimensional Stress Dispersion Technology incorporates biomimetic engineering and dynamic balance principles to minimize external interference. The base’s surface undergoes nano-level polishing, achieving a roughness of ≤0.1μm to provide an ideal reference plane for laser systems. - Seamless Compatibility

Compatible with leading picosecond laser equipment and industrial control systems, the modular design allows customization of dimensions, interfaces, and add-ons (e.g., temperature control, real-time monitoring). This adaptability meets diverse needs, from semiconductor wafer dicing to micro-nano processing. - Sustainability & Longevity

The corrosion-resistant granite material ensures a lifespan exceeding 20 years, reducing long-term maintenance costs. ZHHIMG’s eco-friendly manufacturing process cuts carbon emissions by 30%, aligning with global sustainability standards for high-end industries.

Applications

- Semiconductor Manufacturing: Ensures ±0.5μm consistency in wafer cutting and chip packaging.

- Medical Devices: Enables micron-level machining for surgical robots and optical lenses.

- Aerospace: Provides a stable platform for turbine blades and satellite components.

ZHHIMG Brand Excellence

- Global Partnerships: Collaborates with SAMSUNG, LG, Siemens, and other Fortune 500 leaders, with products deployed in 180+ countries.

- Innovation-Driven: 15% of annual revenue reinvested in R&D, backed by 200+ international patents and industry-standard certifications.

- Premium Support: Offers end-to-end services, from design consultation to post-sale maintenance, with a 48-hour global response time.

Why Choose ZHHIMG?

The ZHHIMG Picosecond Laser Granite Base sets the benchmark for ultra-precision engineering. By merging material science, advanced design, and intelligent manufacturing, we empower clients to achieve breakthroughs in nanoscale precision and accelerate Industry 4.0 advancements.

Contact ZHHIMG today to explore tailored solutions for your high-end manufacturing challenges.

|

Model |

Details |

Model |

Details |

|

Size |

Custom |

Application |

CNC, Laser, CMM... |

|

Condition |

New |

After-sales Service |

Online supports, Onsite supports |

|

Origin |

Jinan City |

Material |

Black Granite |

|

Color |

Black / Grade 1 |

Brand |

ZHHIMG |

|

Precision |

0.001mm |

Weight |

≈3.05g/cm3 |

|

Standard |

DIN/ GB/ JIS... |

Warranty |

1year |

|

Packing |

Export Plywood CASE |

After Warranty Service |

Video technical support, Online support, Spare parts, Field mai |

|

Payment |

T/T, L/C... |

Certificates |

Inspection Reports/ Quality Certificate |

|

Keyword |

Granite Machine Base; Granite Mechanical Components; Granite Machine Parts; Precision Granite |

Certification |

CE, GS, ISO, SGS, TUV... |

|

Delivery |

EXW; FOB; CIF; CFR; DDU; CPT... |

Drawings’ format |

CAD; STEP; PDF... |

Granite precision machine bases are highly regarded in high-end manufacturing and ultra-precision industries for their outstanding performance and reliability. Below, we highlight the key benefits of granite-based systems, such as the ZHHIMG Picosecond Laser Granite Base:

1. **Superior Stability and Vibration Resistance**

The natural composition of granite provides exceptional damping properties, absorbing up to 90% of external vibrations compared to metal bases. This ensures minimal interference during high-precision processes like laser machining or semiconductor wafer cutting, maintaining sub-micron accuracy even in dynamic environments.

2. **Ultra-Low Thermal Expansion**

With a thermal expansion coefficient as low as ≤0.8×10⁻⁶/°C, granite bases remain dimensionally stable across temperature fluctuations. This is crucial for applications requiring long-term consistency, such as optical component manufacturing or aerospace part fabrication, where even minor thermal drift can compromise quality.

3. **Exceptional Surface Flatness and Durability**

Advanced polishing techniques achieve surface roughness levels of ≤0.1μm, creating an ideal reference plane for laser alignment and precision tooling. The natural hardness of granite (Mohs scale 6-7) and its corrosion resistance ensure a lifespan exceeding 20 years, reducing maintenance costs and downtime.

4. **Environmental Sustainability**

Granite is an eco-friendly material with minimal processing requirements. ZHHIMG enhances sustainability through energy-efficient manufacturing processes, reducing carbon emissions by 30% compared to traditional metal base production.

5. **Customizable and Industry-Proven**

Granite bases support modular designs, allowing integration with temperature control systems, real-time monitoring, and compatibility with leading laser brands (e.g., Trumpf, Coherent). Their adaptability makes them indispensable in fields like:

- Semiconductor Manufacturing: Ensures ±0.5μm precision in wafer dicing.

- Medical Device Engineering: Enables micron-level accuracy for surgical robotics.

- Aerospace: Stabilizes critical processes for turbine blade and satellite component production.

**Why ZHHIMG Granite Bases Stand Out**

ZHHIMG leverages the natural advantages of granite combined with proprietary innovations, such as Multi-Dimensional Stress Dispersion Technology and nano-polishing processes. Trusted by Fortune 500 partners like GE, SAMSUNG, LG, our bases deliver nanoscale stability, aligning with Industry 4.0 standards for smart, sustainable manufacturing. We invite you to explore how ZHHIMG's solutions can enhance your precision manufacturing needs.

We use various techniques during this process:

● Optical measurements with autocollimators

● Laser interferometers and laser trackers

● Electronic inclination levels (precision spirit levels)

1. Documents together with products: Inspection reports + Calibration reports(measuring devices) + Quality Certificate + Invoice + Packing List + Contract + Bill of Lading(or AWB).

2. Special Export Plywood Case: Export fumigation-free wooden box.

3. Delivery:

|

Ship |

Qingdao port |

Shenzhen port |

TianJin port |

Shanghai port |

... |

|

Train |

XiAn Station |

Zhengzhou Station |

Qingdao |

... |

|

|

Air |

Qingdao Airport |

Beijing Airport |

Shanghai Airport |

Guangzhou |

... |

|

Express |

DHL |

TNT |

Fedex |

UPS |

... |

1. We will offer technical supports for assembly, adjustment, maintain.

2. Offering the manufacturing &inspection videos from selecting material to delivery, and customers can control and know every detail at anytime anywhere.

QUALITY CONTROL

If you can’t measure something, you can’t understand it!

If you can’t understand it.you cant control it!

If you can’t control it, you can’t improve it!

More information please click here: ZHONGHUI QC

ZhongHui IM, your partner of metrology, help you succeed easily.

Our Certificates & Patents:

Certificates and Patents are an expression of a company’s strength. It’s society’s recognition of the company.

More certificates please click here: Innovation & Technologies – ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (zhhimg.com)