Low MOQ for Granite Machine Parts - Precision Ceramic Mechanical Components – ZHONGHUI

Low MOQ for Granite Machine Parts - Precision Ceramic Mechanical Components – ZHONGHUI Detail:

We deliver products via an integrated production solution from material adjustment to finishing.

ZHHIMG's structural ceramics provide a lot of advantages to customers -- high quality, small products to large products, high degree of freedom in shaping and sizing, low cost, and super short delivery time.

|

Model |

Details |

Model |

Details |

|

Size |

Custom |

Application |

CNC, Laser, CMM... |

|

Condition |

New |

After-sales Service |

Online supports, Onsite supports |

|

Origin |

Jinan City |

Material |

Ceramic(Al2O3, SiC, SiN...) |

|

Color |

White/ Black/ Yellow |

Brand |

ZHHIMG |

|

Precision |

0.001mm |

Weight |

≈3.5g/cm3 |

|

Standard |

DIN/ GB/ JIS... |

Warranty |

1year |

|

Packing |

Export Plywood CASE |

After Warranty Service |

Video technical support, Online support, Spare parts, ... |

|

Payment |

T/T, L/C... |

Certificates |

Inspection Reports/ Quality Certificate |

|

Keyword |

Ceramic Machine Base; Ceramic Mechanical Components; Ceramic Machine Parts; Precision Ceramic |

Certification |

CE, GS, ISO, SGS, TUV... |

|

Delivery |

EXW; FOB; CIF; CFR; DDU; CPT... |

Drawings’ format |

CAD; STEP; PDF... |

● Applicable for manufacturing large-size products exceeding 4 m.

ZHHIMG enables the manufacture of large-size components with micron order precision.

● Short delivery time

ZHHIMG can meet requests for large-size products because it is produced entirely in house from molding and firing to processing.

● Applicable to complicated shapes. High degree of design freedom.

Near-net-shape forming is possible even for casing boards, square boards, long-size boards, disks, rings, and other large-size products.

● No expensive mold needed

Our original technologies require no mold such as rubber molds and plaster molds.

*This varies according to component.

● Readily suited to wide-variety small-lot production. Low cost production.

ZHHIMG easily enables wide-variety small-lot production from a single prototype to mass-production. This results in cost reduction.

● Applicable for mirror-finishing

Ceramics components can be given a mirror-like finish.

● Performance can be improved by replacing existing structural components with ZHHIMG.

(High accuracy, high rigidity, heat resistance, abrasion resistance, corrosion resistance, etc.)

● Compatible with various materials.

Alumina, aluminum titanate, zirconia, aluminum nitride, silicon carbide, silicon nitride...

We use various techniques during this process:

● Optical measurements with autocollimators

● Laser interferometers and laser trackers

● Electronic inclination levels (precision spirit levels)

1. Documents together with products: Inspection reports + Calibration reports(measuring devices) + Quality Certificate + Invoice + Packing List + Contract + Bill of Lading(or AWB).

2. Special Export Plywood Case: Export fumigation-free wooden box.

3. Delivery:

|

Ship |

Qingdao port |

Shenzhen port |

TianJin port |

Shanghai port |

... |

|

Train |

XiAn Station |

Zhengzhou Station |

Qingdao |

... |

|

|

Air |

Qingdao Airport |

Beijing Airport |

Shanghai Airport |

Guangzhou |

... |

|

Express |

DHL |

TNT |

Fedex |

UPS |

... |

1. We will offer technical supports for assembly, adjustment, maintain.

2. Offering the manufacturing &inspection videos from selecting material to delivery, and customers can control and know every detail at anytime anywhere.

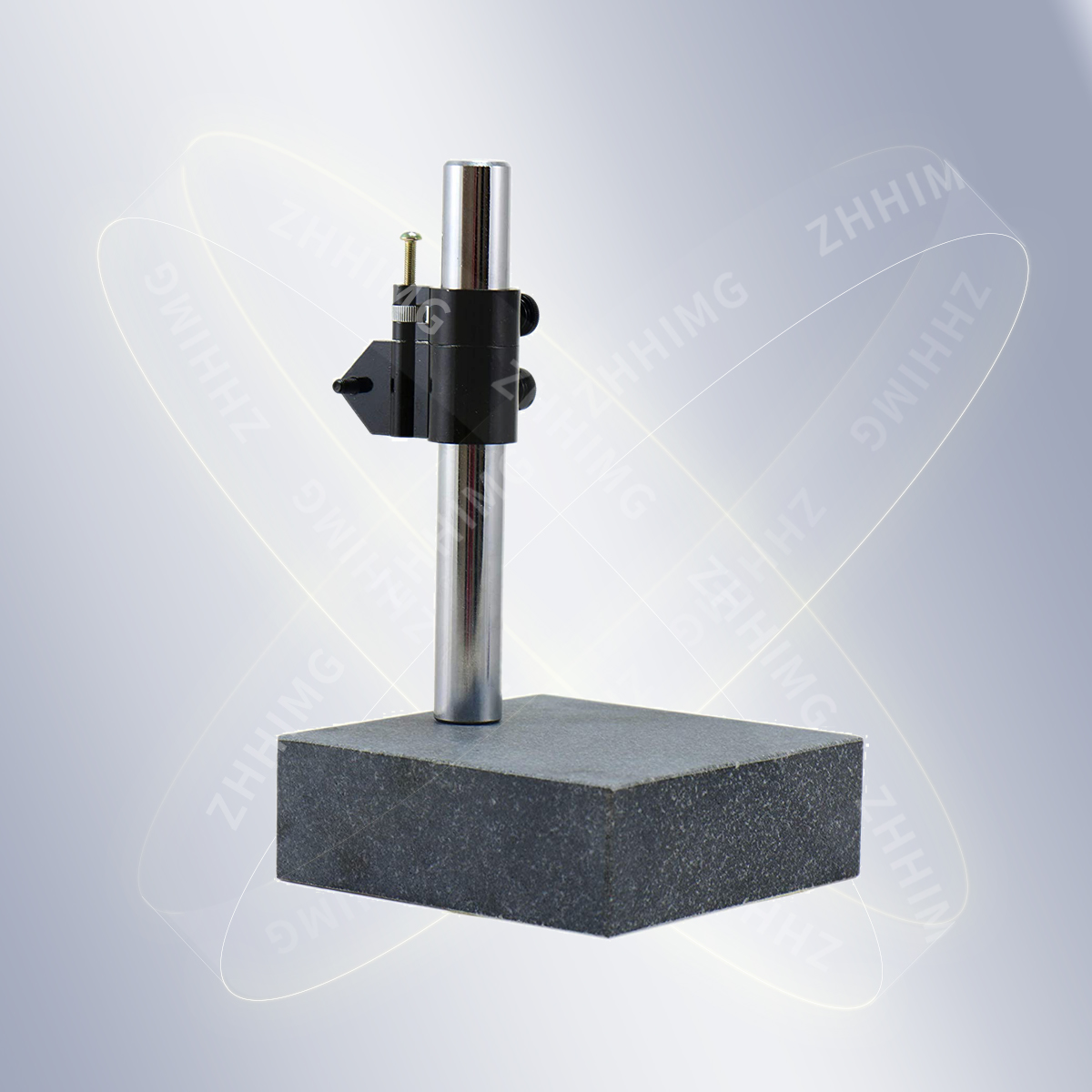

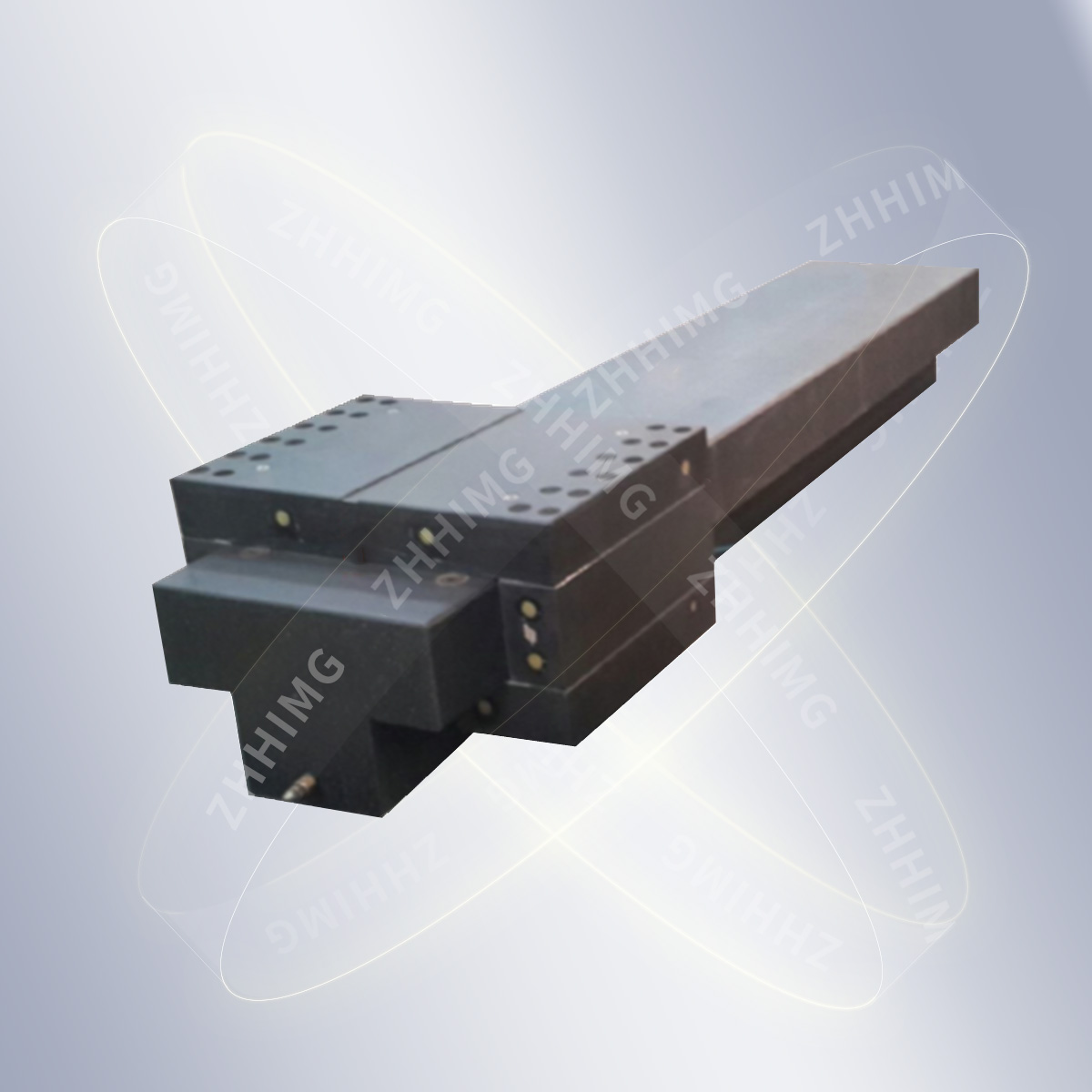

Product detail pictures:

Related Product Guide:

Our advantages are reduced prices,dynamic product sales workforce,specialized QC,solid factories,superior quality services for Low MOQ for Granite Machine Parts - Precision Ceramic Mechanical Components – ZHONGHUI , The product will supply to all over the world, such as: Peru, Roman, Bolivia, We put the product quality and customer's benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, allow us to work together to get success.

QUALITY CONTROL

If you can’t measure something, you can’t understand it!

If you can’t understand it.you cant control it!

If you can’t control it, you can’t improve it!

More information please click here: ZHONGHUI QC

ZhongHui IM, your partner of metrology, help you succeed easily.

Our Certificates & Patents:

Certificates and Patents are an expression of a company’s strength. It’s society’s recognition of the company.

More certificates please click here: Innovation & Technologies – ZHONGHUI INTELLIGENT MANUFACTURING (JINAN) GROUP CO., LTD (zhhimg.com)

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.