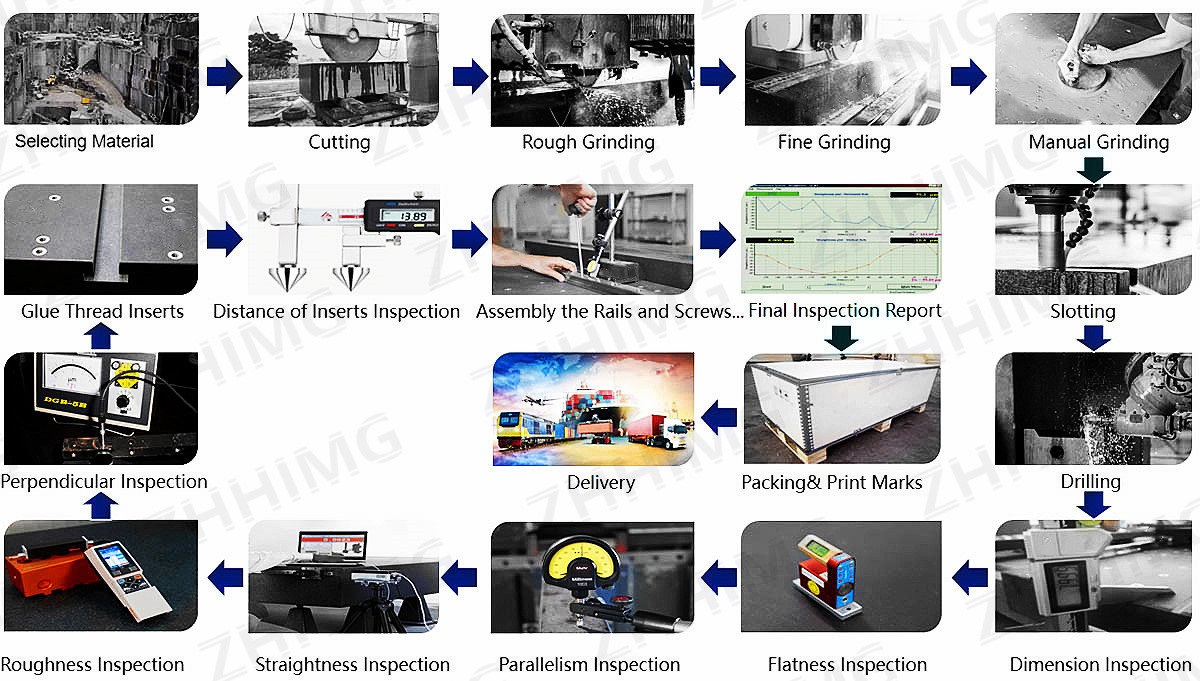

Precision Granite Manufacturing Process

ZhongHui Intelligent Manufacturing

Selecting Material: Select good nature granite. To check color(white line and spots), whether there is crack or not and check the Physical Properties Analysis Report.

Cutting Material: Cut the granite into similar size with final products(little more than 5mm).

Rough Grinding: grinding flatness and dimension size into size little more than final dimension 1mm.

Fine Grinding: grinding flatness within 0.01mm.

Manual Grinding: make the accuracy (flatness, perpendicular, parallelism) reach the requirements in the drawings.

Slotting & Drilling: Make slots and drill holes for inserts & cutting weight.

Dimension Inspection: Inspect & Measuring length, width and thickness and so on dimension size.

Precision Inspection: Inspect the flatness, parallelism, perpendicular

Glue Inserts & Inspection: Glue Thread Inserts and inspect the distance and torque.

Assembly rails, screws...& Inspection: assembly and calibration and inspection.

Package & Delivery: assembly on site.