Zhonghui Intelligent Manufacturing Group(ZHHIMG) has found and tested a lot of granite in the world to find the best granite material.

Granite Source

Why Choose Granite?

• DIMENSIONAL STABILITY: black granite is a natural aged material formed over millions of years and therefore displays great internal stability.

• THERMAL STABILITY: the linear expansion is much lower than the steel or cast iron ones.

• HARDNESS: comparable to good-quality tempered steel.

• WEAR RESISTANCE: instruments last longer.

• ACCURACY: the flatness of the surfaces is better than the one obtained with traditional materials.

• RESISTANCE TO ACIDS, NON-MAGNETIC ELECTRICAL INSULATION RESISTANCE TO OXIDATION: no corrosion, no maintenance.

• COST: working the granite with state-of-the-art technology prices are lower.

• OVERHAUL: Eventual servicing can be carried out quickly and cheaply.

Global Main Granite Material

Mountain Tai (Jinan Black Granite)

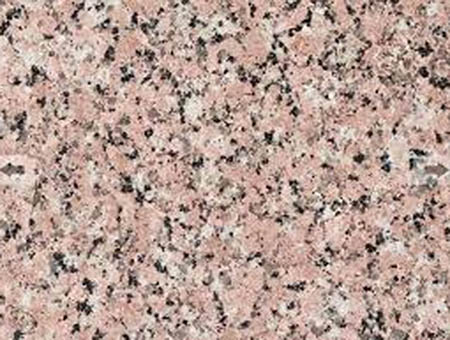

Pink Granite (USA)

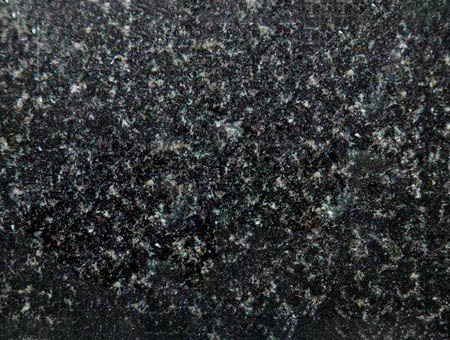

Indian Black Granite (K10)

Charcoal Black (USA)

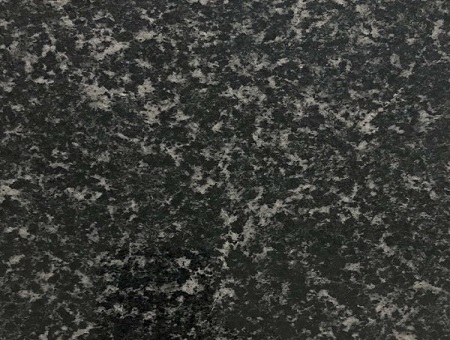

Indian Black Granite (M10)

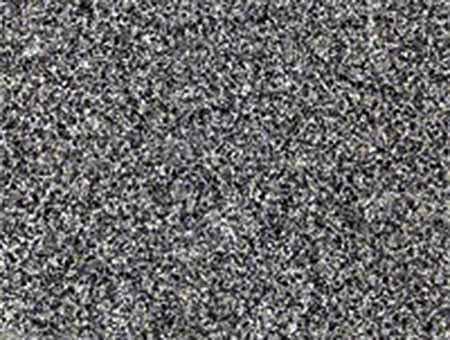

Academy Black (USA)

African Black Granite

Sierra White (USA)

Jinan Black Granite II (Zhangqiu Black Granite)

FuJian Granite

SiChuan Black Granite

DaLian Grey Granite

Austria Grey Granite

Blue Lanhelin Granite

Impala Granite

China Black Granite

There are many kinds of granite in the world, and these nine kinds of stone are mainly used now. Because these nine kinds of stones have better physical properties than other granite. Especially Jinan black granite, which is the best granite material we've ever know in precision field. HEXAGON, China AEROSPACE...all choose Black Granite.

Global Main Granite Material Analysis Reports

| Material Items Origin | Jinan Black Granite | Indian Black Granite(k10) | South African Granite | Impala Granite | Pink Granite | Zhangqiu Granite | Fujian Granite | Austria Grey Granite | Blue Lanhelin Granite |

| Jinan,China | India | South Africa | South Africa | America | Jinan, China | Fujian,China | Austria | Italy | |

| DENSITY(g/cm3) | 2.97-3.07 | 3.05 | 2.95 | 2.93 | 2.66 | 2.90 | 2.9 | 2.8 | 2.6-2.8 |

| Water Absorption(%) | 0.049 | 0.02 | 0.09 | 0.07 | 0.07 | 0.13 | 0.13 | 0.11 |

0.15 |

| Coefficient of Termal Expansion 10-6/℃ |

7.29 | 6.81 | 9.10 | 8.09 |

7.13 | 5.91 | 5.7 | 5.69 |

5.39 |

| Flexural Strength (MPa) | 29 | 34.1 | 20.6 | 19.7 | 17.3 | 16.1 | 16.8 | 15.3 | 16.4 |

| Compressive strength(MPa) | 290 | 295 | 256 | 216 | 168 | 219 | 232 |

206 | 212 |

| Modulus of Elasticity(MOE) 104mpa | 10.6 | 11.6 | 10.1 | 8.9 |

8.6 | 5.33 | 6.93 | 6.13 | 5.88 |

| Poisson's Ratio | 0.22 | 0.27 | 0.17 | 0.17 |

0.27 | 0.26 | 0.29 | 0.27 |

0.26 |

| Shore Hardness | 93 | 99 | 90 | 88 | 92 | 89 | 89 |

88 |

|

| Modulus of Rupture(MOR) (MPA) | 17.2 | ||||||||

| Volume Resistivity(Ωm) | 5~6 x107 | 5~6 x107 | 5~6 x107 | 5~6 x107 | 5~6 x107 | 5~6 x107 | 5~6 x107 | 5~6 x107 | 5~6 x107 |

| Resistance Rate(Ω) | 9 x 106 | 9 x 106 | 9 x 106 | 9 x 106 | 9 x 106 | 9 x 106 | 9 x 106 | 9 x 106 | 9 x 106 |

| Natural Radioactivity |

1. The material testing experiments were initiated by Zhonghui Intelligent Manufacturing (Jinan) Group Co., Ltd.

2. Six samples of each type of granite were tested, and the test results were averaged.

3. The experimental results are only responsible for the test samples.