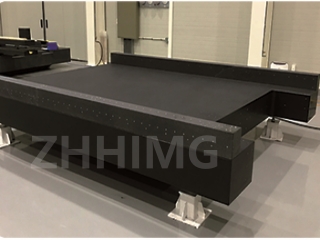

In the field of ultra-precision motion control, the air float ultra-precision motion module has become an ideal choice for many high-end manufacturing and scientific research scenarios due to its frictionless and high-precision motion characteristics. The introduction of granite precision base is to inject strong power for its performance improvement, but the combination of the two is not perfect.

First, significant advantages

Excellent stability: Granite after millions of years of geological changes, the internal structure is dense and uniform, mainly by quartz, feldspar and other minerals closely combined. This unique structure gives the granite base excellent stability. In the face of external interference, such as the vibration generated by the operation of surrounding large equipment and the fluctuation of ambient temperature, granite base can effectively block and attenuate. In the electronic chip manufacturing workshop, machine tools and other equipment operate frequently, and the granite base can reduce the vibration amplitude of the ultra-precision motion module transmitted to the air float by more than 80%, ensuring the smooth movement of the module, providing a stable foundation for the high-precision processes such as lithography and etching in the chip manufacturing process, and greatly improving the yield of chip manufacturing.

Ultra-high accuracy retention: The ultra-precision motion module of the air float requires extremely high accuracy, and the advantage of the low expansion coefficient of the granite base plays a key role in this. The thermal expansion coefficient of general granite is 5-7 ×10⁻⁶/℃, which is much lower than common metal materials. When the temperature changes, the base size changes very little. In the field of astronomy, the ultra-precision motion module of the air float for the fine tuning of the telescope lens, with the granite base, can ensure that the positioning accuracy of the lens is maintained at the sub-micron level even if the temperature difference between day and night is large, helping astronomers to clearly observe distant celestial bodies.

Good wear resistance and long life: Although the air floating ultra-precision motion module reduces direct friction during operation, there is still a certain degree of wear risk in long-term use. Granite hardness is high, Mohs hardness can reach 6-7, strong wear resistance. In the materials science laboratory, the frequently used air float ultra-precision motion module, granite base can effectively resist the friction of the air float slider, compared with the ordinary metal base, can extend the maintenance cycle of the module by more than 50%, reduce equipment maintenance costs, and ensure the continuity of scientific research work.

Second, there are shortcomings

High cost: The acquisition cost of high-quality granite raw materials is high, and its mining, transportation and processing are more complex, requiring professional equipment and technology. From mining the appropriate granite ore to processing into the ultra-precision air floating motion module base that meets the requirements of high precision, it involves many fine processes, such as high-precision cutting, grinding, polishing, etc., which makes the manufacturing cost of granite precision base greatly increase. Compared with other materials such as metal, the cost can be several times or more higher, which limits its large-scale application to a certain extent, especially for small enterprises or scientific research institutions with limited budgets.

Heavier weight: The density of granite is relatively large, about 2.6-3.1g /cm³, resulting in a heavier granite precision base. In the process of equipment installation and handling, professional lifting equipment and manpower are required, which increases the difficulty of installation and transportation costs. In some scenarios that require high flexibility of equipment spatial layout, the heavy base also restricts the convenient movement and reinstallation of the ultra-precision motion module of the air float, affecting the efficiency and adaptability of the equipment.

It is difficult to process: granite has high hardness and brittleness, and the processing equipment and process requirements are extremely strict. In the process of machining, it is easy to have cracks, cracks and other defects, and it is difficult to ensure the machining precision and surface quality. In order to achieve the high-precision flatness and straightness required by the ultra-precision motion module of the air float, many tests and corrections are required during the processing process, and the processing cycle is long and the rejection rate is high, which further increases the production cost and time cost.

The ultra-precision motion module with the granite precision base has outstanding advantages in stability and accuracy, which is suitable for high-end fields with high precision requirements, but the short board such as cost, weight and processing difficulty also needs to be comprehensively considered in practical applications, and a reasonable choice is made after weighing the advantages and disadvantages.

Post time: Apr-08-2025