The design and manufacturing of granite inspection benches play a crucial role in precision engineering and quality control across various industries. These specialized work surfaces are essential for measuring and inspecting components with high accuracy, ensuring that products meet stringent specifications and standards.

Granite is the material of choice for inspection benches due to its inherent properties. It is non-deformable, stable, and resistant to temperature fluctuations, making it ideal for maintaining precision over time. The manufacturing process begins with selecting high-quality granite blocks, which are then cut and polished to create a flat, smooth surface. This meticulous process ensures that the bench can provide reliable measurements, which is vital in fields such as aerospace, automotive, and manufacturing.

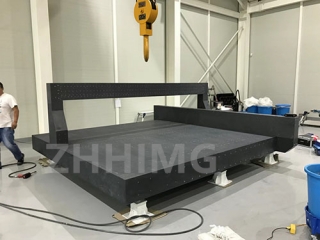

The design of a granite inspection bench involves careful consideration of various factors, including size, shape, and additional features. Customization is often necessary to meet specific industry requirements. For instance, some benches may include T-slots for clamping fixtures, while others might have integrated measuring systems for enhanced functionality. Ergonomics also play a significant role in the design, ensuring that operators can work comfortably and efficiently.

Once the design is finalized, the manufacturing process incorporates advanced techniques such as CNC machining and precision grinding. These methods ensure that the granite surface achieves the required flatness and surface finish, which are critical for accurate measurements. After manufacturing, the benches undergo rigorous quality checks to guarantee that they meet industry standards.

In conclusion, the design and manufacturing of granite inspection benches are vital for ensuring precision in measurement and inspection processes. By leveraging the unique properties of granite and employing advanced manufacturing techniques, industries can achieve the high levels of accuracy necessary for quality control and product integrity.

Post time: Nov-06-2024