Granite air flotation platforms are an effective solution for industrial and commercial applications. This is an advanced technology that uses compressed air to suspend heavy objects on a cushion of air, making it easy to move large and heavy items. It is commonly used in construction, transportation, and sectors where large machinery needs to be moved. A question that is often asked about granite air flotation platforms is whether they require constant maintenance to keep them in good working order. In this article, we will explore this topic and provide an answer to this question.

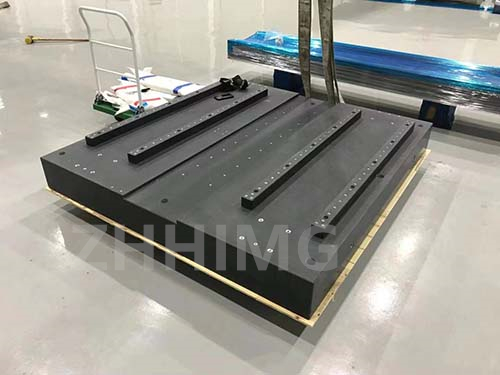

Granite air floating platforms are an efficient and reliable technology that requires minimal maintenance. It is simple in design and does not require much technical skill to operate and maintain. The system consists of a series of air bags that are pumped into compressed air, which levitates the load on an air cushion. The granite platform itself is made of high-quality granite that is resistant to wear and tear and is designed to last for decades without any major maintenance.

However, like all modern technologies, granite air flotation platforms require a certain level of maintenance to ensure that they remain functional and efficient. Maintenance requirements depend primarily on frequency of use and other operational factors. For example, if the platform is used for heavy-duty applications, such as moving large containers, it may require more frequent maintenance than if it were used for light-duty applications.

Common maintenance procedures for granite air floating platforms include regular cleaning, lubrication of moving parts, inspection of air bags, inspection of compressors and air supply systems. The cleaning process includes the removal of any dirt, dust or debris that may have accumulated on the surface of the platform. This helps prevent airbag damage and ensures that the platform remains clean and hygienic.

The lubrication process involves applying the appropriate lubricant to all moving parts to reduce friction and wear. This helps to extend the service life of the platform and keep it running smoothly. Inspecting the airbag is also crucial to detect any signs of wear or damage that may need to be replaced.

Finally, checking the compressor and gas supply system is critical to ensure a consistent supply of compressed air to the platform. Any issues with the gas supply system should be addressed immediately to prevent downtime or damage to the platform.

In short, granite air floating platforms are a highly reliable and efficient technology that requires minimal maintenance. However, a certain level of maintenance is required to keep the platform in good working order. Regular cleaning, lubrication, inspection of air bags, inspection of compressors and gas supply systems are some of the basic maintenance procedures of granite air flotation platforms. By following these steps, the platform can be used for decades without major repairs or replacement, providing a cost-effective solution for many industrial and commercial applications.

Post time: May-06-2024