The use of granite components in Coordinate Measuring Machines (CMM) is widespread due to its natural resistance to wear, thermal stability, and dimensional stability. However, like any other material, granite may be vulnerable to external factors such as dust, moisture, and environmental pollution, which may affect the accuracy and precision of CMM readings.

To prevent the infringement of external factors on the granite components of a CMM, special protective treatment may be required. The treatment should be done regularly to ensure the longevity of the granite components and maintain the overall efficiency of the CMM.

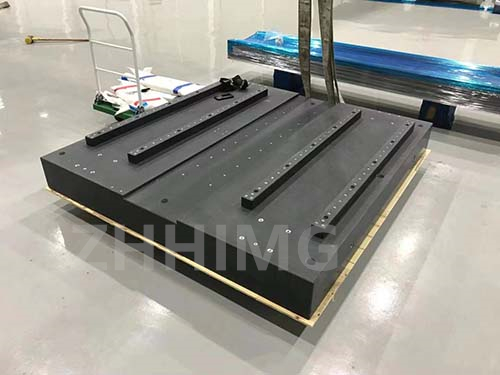

One of the common ways of protecting granite components is through the use of covers and enclosures. Covers are designed to protect against dust and other airborne particles that may settle on the granite surface. Enclosures, on the other hand, are used to protect the granite from moisture which can cause the formation of rust and corrosion.

Another form of protective treatment is through the use of sealants. Sealants are designed to keep out moisture from reaching the granite surface. They are applied to the surface of the granite and left to dry to ensure that they are completely cured before use. Once the sealant is cured, it forms a protective barrier against moisture.

The use of air-conditioning and dehumidifiers can also be beneficial in protecting the granite components of the CMM. These devices help to regulate the temperature and humidity of the environment where the CMM is located. Maintaining a controlled environment can help to reduce the risk of damage to the granite components caused by changes in temperature and humidity.

Regular cleaning and maintenance are also important in protecting granite components. Cleaning should be done using a soft cloth or brush to avoid scratching the surface of the granite. In addition, cleaning agents that are pH neutral should be used to avoid corroding the surface of the granite. Regular maintenance should also be conducted to check for signs of wear and tear and address them before they escalate.

In conclusion, the use of granite components in CMMs offers several benefits. However, protective treatment is necessary to ensure their longevity and maintain the accuracy and precision of the CMM. Regular protective treatment, cleaning, and maintenance should be conducted to protect against external factors. Ultimately, effective protection of the granite components will help to improve the overall efficiency and accuracy of the CMM, ensuring that it can reliably serve its intended purpose for many years to come.

Post time: Apr-11-2024