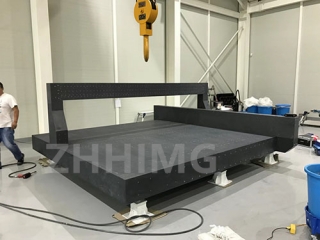

In the semiconductor manufacturing workshop, the requirements of the chip manufacturing process for environmental conditions and equipment accuracy are extreme, and any slight deviation may lead to a significant decline in the chip yield. The XYZT precision gantry movement platform relies on granite components to collaborate with other parts of the platform to build a solid foundation for achieving nanoscale accuracy.

Excellent vibration blocking properties

In the semiconductor manufacturing workshop, the operation of peripheral equipment and personnel walking around may cause vibration. The internal structure of granite components is dense and uniform, with natural high damping characteristics, like an efficient vibration "barrier". When the external vibration is transmitted to the XYZT platform, the granite component can effectively attenuate more than 80% of the vibration energy and reduce the interference of vibration on the platform motion accuracy. At the same time, the platform is equipped with a high-precision air float guide system, which works in conjunction with granite components. The air float guide uses the stable gas film formed by high pressure gas to realize the contactless suspension movement of the moving parts of the platform and reduce the small vibration caused by mechanical friction. Together, the two ensure that the platform positioning accuracy is always maintained at the nanometer level in key processes such as chip lithography and etching, and avoid the deviation of chip circuit patterns caused by vibration.

Excellent thermal stability

The fluctuation of temperature and humidity in the workshop has a great influence on the accuracy of chip manufacturing equipment. The thermal expansion coefficient of granite is very low, generally in 5-7 ×10⁻⁶/℃, the size is almost unchanged when the temperature changes. Even if the temperature difference between day and night in the workshop or the heat production of the equipment causes the ambient temperature to fluctuate, the granite components can remain stable to prevent the deformation of the platform due to thermal expansion and contraction. At the same time, the intelligent temperature control system equipped with the platform monitors the ambient temperature in real time, automatically adjusts the air conditioning and heat dissipation equipment, and maintains the workshop temperature at 20 ° C ±1 ° C. Combined with the advantages of granite heat stability, ensure that the platform in long-term operation, the movement accuracy of each axis always meet the chip manufacturing nanometer precision standards, to ensure that the chip lithography pattern size is accurate, etching depth is uniform.

Meet the needs of clean environment

The semiconductor manufacturing shop needs to maintain a high degree of cleanliness to prevent dust particles from contaminating the chip. Granite material itself does not produce dust, and the surface is smooth, not easy to absorb dust. The platform as a whole adopts a fully closed or semi-closed structure design to reduce the entry of external dust. The internal air circulation system is linked with the clean air conditioning system of the workshop to ensure that the internal air cleanliness reaches the level required by chip manufacturing. In this clean environment, granite components will not affect the performance due to dust erosion, and key components such as high-precision sensors and motors of the platform can also operate stably, providing continuous and reliable nanoscale accuracy guarantee for chip manufacturing, and helping the semiconductor industry to move to a higher process level.

Post time: Apr-14-2025