Granite vs. Cast Iron Lathe Bed: Which is Better for Heavy Loads and Impacts?

When it comes to choosing a material for a lathe bed that can withstand heavy loads and impacts, both granite and cast iron are popular choices. Each material has its own unique properties that make it suitable for different applications, but which one is better for withstanding heavy loads and impacts?

Cast iron is a popular choice for lathe beds due to its high strength and durability. The material is capable of withstanding heavy loads and impacts, making it ideal for use in industrial settings where the lathe is subjected to rigorous use. The structure of cast iron allows it to absorb vibrations and provide stability during machining operations, making it a reliable choice for heavy-duty applications.

On the other hand, granite is also a popular material for lathe beds due to its high level of stability and resistance to wear and tear. The natural properties of granite make it an excellent choice for applications where precision and stability are crucial. However, when it comes to withstanding heavy loads and impacts, cast iron has the upper hand.

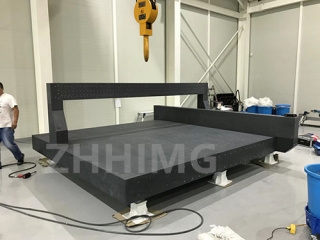

The mineral casting machine bed, on the other hand, is a newer alternative that offers a combination of both granite and cast iron properties. The mineral casting material is a blend of natural granite aggregates and epoxy resin, resulting in a material that is highly resistant to wear and tear, as well as capable of withstanding heavy loads and impacts. This makes it a strong contender for applications where both precision and durability are essential.

In conclusion, while both granite and cast iron are capable of withstanding heavy loads and impacts, the cast iron lathe bed is known for its exceptional strength and durability in industrial settings. However, the mineral casting machine bed offers a promising alternative that combines the best properties of both granite and cast iron, making it a strong contender for applications that require both precision and resilience. Ultimately, the choice between granite, cast iron, and mineral casting will depend on the specific requirements of the lathe application and the level of durability and precision needed.

Post time: Sep-12-2024