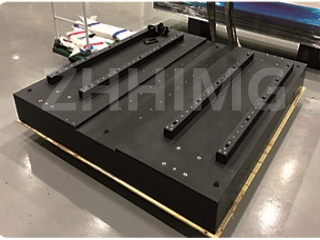

CMM stands for Coordinate Measuring Machine. These machines are used for dimensional measurement in a variety of industries. Granite components are the most popular material used in CMMs because of their durability and stability. In this article, we will explore how the rigidity and damping characteristics of granite components affect mechanical vibration in CMM.

Rigidity Characteristics

Rigidity is defined as the resistance of a material to deformation. The rigidity of granite components is high, which makes them an excellent material for use in CMMs. It means that granite components are resistant to bending or flexing under load, which is critical when precise measurements are being taken.

Granite components are made from high-density granite that is free of any impurities or voids. This uniformity in the granite ensures that the material has consistent mechanical properties, which translates to high rigidity. The high rigidity of granite components means that they can maintain their shape and form even under heavy loads.

Damping Characteristics

Damping is the measure of a material's ability to reduce or absorb mechanical vibrations. In CMMs, mechanical vibrations can be detrimental to the accuracy of measurements. Granite components have excellent damping characteristics that can help reduce the effects of mechanical vibrations.

Granite components are made from dense material, which helps to dampen mechanical vibrations. This means that when a CMM is in use, granite components can absorb the mechanical vibrations that occur due to the machine's motion. With these vibrations absorbed, the measurements obtained by the CMM are more accurate.

The combination of high rigidity and damping characteristics means that granite components are an ideal material for use in CMMs. The high rigidity ensures that the machine's components maintain their shape and form, while the damping characteristics help to absorb mechanical vibrations, leading to more accurate measurements.

Conclusion

In conclusion, the use of granite components in CMMs is vital in ensuring the accuracy of measurements. The rigidity of granite components helps to maintain the shape and form of machine components, while the damping characteristics help to absorb mechanical vibrations, leading to more accurate measurements. The combination of these two characteristics makes granite components the ideal material for use in CMMs.

Post time: Apr-11-2024