Granite bases are essential components for CNC (Computer Numerical Control) machines.

These bases provide a stable foundation for the machine tool, which is crucial for accuracy and precision during the manufacturing process. Therefore, the size and shape of the granite base must adapt to the different CNC machine tool needs.

Manufacturers of CNC machines use various types of materials for the base, but granite is the most popular choice due to its high density and low vibration properties. Granite is an ideal material for machine bases as it can maintain its shape under extreme conditions, including high temperatures and constant mechanical stresses.

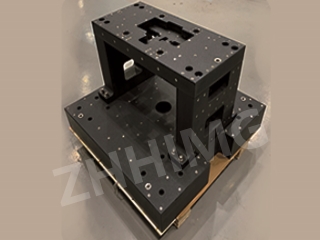

CNC machine manufacturers offer a range of sizes and shapes for the granite base, which can vary depending on the size and weight of the machine. For large CNC machines, the base can take the shape of a rectangular box or a T-shaped design. This design provides maximum stability and rigidity and is indispensable for the heavy-duty cutting processes.

In contrast, smaller CNC machines will need a smaller-sized granite base. The shape of the base can differ, depending on the shape and size of the machine. Small machines may require a rectangular or square-shaped base, which will provide adequate stability and rigidity for processing small to medium-sized parts.

It is vital to note that the base size and shape must be carefully considered when designing a CNC machine. The design of a machine will determine the type of manufacturing process, the size and weight of the material being processed, and the tolerances required. These factors will then determine the size and shape of the machine base.

Another benefit of the granite base is its ability to dampen vibrations that may be generated during the machine's operation. Granite has a low coefficient of thermal expansion, which means it will not expand or contract significantly due to temperature changes, ensuring the machine's accuracy.

The strength of the granite base is also an important factor in providing support for the machine's moving parts. Therefore, the granite must be of high quality, free from any cracks, and have high resistance to wear and tear.

In conclusion, the size and shape of the granite base must adapt to different CNC machine tool needs. The design of the machine will determine the size and shape of the base required for it. Therefore, manufacturers must consider the type of work the CNC machine will be carrying out, the weight and size of the material being processed, the required accuracy and precision, and the level of vibrations generated during the process to ensure a stable foundation for the machine tool. Ultimately, a suitable granite base will help provide improved machine performance and greater accuracy and precision that can benefit many industries that rely on CNC machines.

Post time: Mar-26-2024