In the modern era of technology, CNC equipment has become an integral part of the manufacturing industry. It is widely used in various fields for providing precision and accuracy to the production process. One of the crucial components of CNC equipment is the granite bed. The accuracy and stability of the granite bed are essential for the precise functioning of the CNC equipment. In this article, we will discuss some essential steps to ensure accuracy and stability in the production process of the granite bed.

Firstly, the selection of high-quality granite is crucial in ensuring the accuracy and stability of the granite bed. The granite should be of uniform texture and free from cracks or defects. High-quality granite will also have a minimal coefficient of thermal expansion, which ensures that the bed's dimensions remain stable while undergoing different temperature changes during the production process.

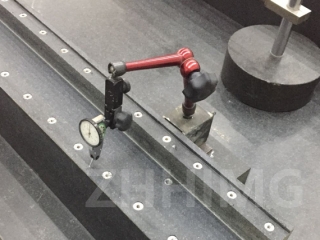

Secondly, the leveling of the granite bed is highly important in ensuring accuracy. The accuracy of the bed's flatness should be within microns, and it should be leveled using precision-grade leveling tools. This will ensure that the CNC equipment functions smoothly and with precision.

Thirdly, the use of precision bearings in the granite bed is crucial for maintaining stability during the production process. The bearings should be pre-loaded to ensure that any external forces do not affect the bed's stability. Also, the bearings should be precisely positioned, and their mounting should be vibration-free.

Fourthly, the maintenance of the granite bed is crucial for ensuring accuracy and stability during the production process. The bed must be regularly cleaned and kept free from any dirt or debris that may affect its performance. Additionally, the bearings should be lubricated regularly to ensure they function smoothly.

Lastly, a skilled and experienced team should be put in charge of the production process. They must be trained in the equipment's functionality and maintain a constant check on the equipment's performance. This will ensure that any issues are detected early on and rectified quickly.

In conclusion, the production process of granite beds for CNC equipment requires attention to detail and constant monitoring to ensure accuracy and stability. From the selection of high-quality granite to regular maintenance and the use of precision bearings, the production process involves various critical steps that determine the granite bed's overall performance. With proper care and attention, the granite bed can provide precision and accuracy to CNC equipment for years to come.

Post time: Mar-29-2024