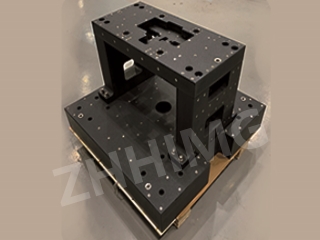

Precision granite components are widely used in various industries, including aerospace, automotive, and semiconductor manufacturing. These components are highly valued for their dimensional stability, durability, and resistance to wear. One of the key characteristics of precision granite components is uniform texture. The texture uniformity of these components is critical for ensuring their performance and accuracy. In this article, we will discuss how to ensure the texture uniformity of precision granite components.

1. Proper material selection

The first step in ensuring the texture uniformity of precision granite components is to choose the right material. Granite is a natural stone that varies in texture and color. Therefore, it is important to select granite blocks that have a consistent texture. High-quality granite blocks are sourced from quarries that produce a consistent grain size and texture. This helps to ensure that the finished components will have a uniform texture.

2. Precise cutting and shaping

The next step in ensuring the texture uniformity of precision granite components is precise cutting and shaping. This involves using advanced CNC machines to accurately cut and shape the granite blocks. CNC machines are able to achieve a very high level of precision and accuracy, ensuring that each component has the same shape and texture.

3. Proper polishing techniques

After cutting and shaping, the components are polished to achieve a smooth surface and uniform texture. Proper polishing techniques are critical in achieving texture uniformity. Different polishing pads with varying grits are used to achieve a smooth finish without altering the texture of the granite.

4. Quality control

Finally, quality control is essential in ensuring the texture uniformity of precision granite components. Each component is inspected using advanced measuring equipment to ensure that it meets the required specifications. Any components that do not meet the required standards are discarded or reworked to achieve the desired texture uniformity.

In conclusion, the texture uniformity of precision granite components is critical for ensuring their performance and accuracy. Proper material selection, precise cutting and shaping, proper polishing techniques, and quality control are all essential in achieving texture uniformity. By following these steps, manufacturers can produce high-quality precision granite components that meet the needs of their customers in various industries.

Post time: Mar-12-2024