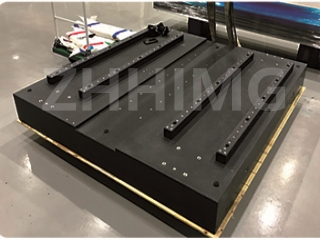

Granite is one of the most common materials used for the base of CNC machine tools due to its excellent durability, stability, and precision. However, vibrations and noise can occur during the operation of CNC machines, which can have a negative impact on the performance and accuracy of the machine. In this article, we'll discuss some ways to reduce vibration and noise when granite base is used for CNC machine tools.

1. Proper Installation

One of the most important factors to consider when using a granite base for a CNC machine tool is proper installation. A granite base must be leveled and secured firmly to the floor to prevent any movement that could cause vibration. When installing a granite base, anchor bolts or epoxy grout can be used to secure it to the floor. The base should also be checked periodically to ensure that it remains level and secure.

2. Isolation Mats

Another effective solution to reduce vibration and noise is to use isolation mats. These mats are designed to absorb vibration and shock and can be placed underneath the machine to reduce the transmission of vibration to the floor and surrounding areas. The use of isolation mats can significantly improve the performance and accuracy of the machine while reducing unwanted noise.

3. Damping

Damping is a technique that involves adding material to the machine to reduce unwanted vibration and noise. This technique can be applied to the granite base by using materials such as rubber, cork, or foam. These materials can be placed between the base and the machine to reduce vibration and noise. Properly designed and placed damping material can effectively reduce the occurrence of resonant frequencies that can cause vibration in the machine.

4. Balanced Tooling

Balanced tooling is essential for reducing vibration and noise. The tool holders and the spindle of the CNC machine tool must be balanced to avoid excessive vibration during operation. Unbalanced tooling can cause excessive vibration that can negatively affect the performance and accuracy of the machine. Maintaining a balanced tooling system can significantly reduce the occurrence of unwanted vibration and noise in the CNC machine tool.

Conclusion

Using a granite base for CNC machine tools is an excellent choice for stability and precision. However, vibration and noise can occur during the operation of the machine. By following the techniques mentioned above, you can effectively reduce vibrations and noise. Proper installation, isolation mats, damping, and balanced tooling are all effective ways to achieve a smoother and quieter operation of CNC machines while maintaining high levels of precision.

Post time: Mar-26-2024