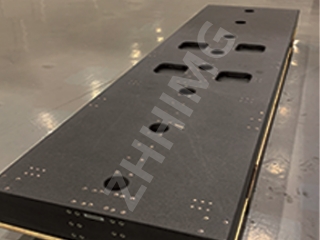

Granite is a popular material used in the manufacturing process of optical waveguide positioning devices due to its high stability, durability, and resistance to deformation. Granite assembly is commonly used in the construction of optical waveguide positioning devices because of its robustness, which ensures that the device remains stable during use and is not easily damaged.

In this article, we will discuss how to use and maintain a granite assembly for your optical waveguide positioning device. These tips will help you to keep your device in good working order, extend its shelf life, and improve its accuracy.

1. Handling and Installation

The first step in using a granite assembly for your optical waveguide positioning device is proper handling and installation. When handling the granite assembly, it is important to avoid bumping or dropping it. Always handle the granite assembly firmly, as any damage can affect the accuracy of the device.

When installing the optical waveguide positioning device, make sure that the granite assembly is level and stable. This will ensure that the accuracy of the device is maintained over time.

2. Cleaning

Cleaning the granite assembly regularly is vital to ensure that the surface remains smooth and free from dust or debris. You should use a soft cloth or brush to remove any dirt or debris from the surface of the granite assembly. A soft brush or cloth will prevent any scratches or other damage to the granite assembly.

When cleaning the granite assembly, avoid using harsh or abrasive chemicals as this can damage the polished finish. Instead, use a mild detergent and warm water to clean the surface of the granite assembly. After washing, rinse the surface with clean water and dry it with a soft cloth.

3. Maintenance

Maintenance of your granite assembly is essential to ensure the longevity of your optical waveguide positioning device. Regular maintenance checks can help detect any potential problems before they become major issues. Check for signs of wear and tear, such as cracks, chips, or dents, on the surface of the granite assembly. Any damage to the surface of the granite assembly can affect the accuracy of the device and must be repaired immediately.

Additionally, it is recommended to perform regular calibration checks to ensure that the optical waveguide positioning device is operating within the specified accuracy limits. Regular calibration checks can improve the accuracy of the device and extend its lifespan.

4. Storage

When storing the optical waveguide positioning device, it is important to keep it in an appropriate environment. The device should be stored in a dry, cool place, away from any sources of heat, moisture or direct sunlight. This will prevent any damage or distortion that may affect the accuracy of the device.

In conclusion, proper use and maintenance of a granite assembly for your optical waveguide positioning device are essential in ensuring accuracy, precision, and longevity. At all times, handle the granite assembly firmly, keep it clean and free from debris, maintain the device regularly, and store it in an appropriate environment. By adhering to these tips, you will be able to keep your optical waveguide positioning device in good working order, and achieve accurate and reliable results every time.

Post time: Dec-04-2023