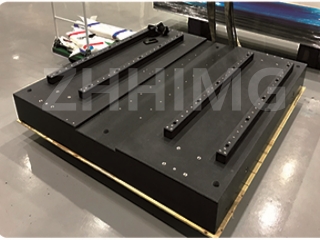

Granite air bearing stages are highly precise positioning systems that are used in various industrial and research applications. These stages provide high-precision and smooth motion with no friction or wear, which makes them excellent tools for applications that require precise movement. In this article, we will discuss the different aspects of using granite air bearing stages.

1. Mounting and Setup

Before using a granite air bearing stage, it is essential to ensure that it is correctly mounted and set up. It is recommended to use a solid mounting surface that can accommodate the weight of the stage while providing a stable base. It is also important to ensure that the stage is level, as any tilt or imbalance can affect its performance.

The setup process usually involves connecting the stage to the controller and configuring the controller for the desired motion and accuracy. It is important to follow the manufacturer's instructions for the setup process to ensure proper operation of the system.

2. Operating the System

Once the granite air bearing stage is set up, it can be operated using the controller. The controller provides various methods for motion control, including manual operation, positioning, and programming.

In manual operation mode, the user can control the motion of the stage using a joystick, buttons, or other control devices. This mode is useful for positioning and alignment tasks that require real-time adjustments.

In positioning mode, the user can set specific positions for the stage to move to. The controller will automatically move the stage to the target position with a high degree of accuracy.

In programming mode, the user can create complex motion paths using software. This mode is useful for applications that require a sequence of movements or coordinated motion with other systems.

3. Maintenance

To ensure proper and reliable operation, it is essential to perform regular maintenance on the granite air bearing stage. This involves cleaning the stage, checking for any signs of wear or damage, and lubricating the air bearings.

It is also essential to keep the air supply clean and dry to avoid any contamination or damage to the air bearings. The air filters must be changed regularly, and the system should be inspected for any leaks or blockages.

Conclusion

In conclusion, granite air bearing stages are essential tools for high-precision positioning in various industrial and research applications. Proper mounting and setup, operation, and maintenance are crucial for efficient and reliable operation of the stage. With the benefits of high precision, smooth motion without friction or wear, and easy programming, granite air bearing stages are becoming increasingly popular as a must-have tool in many applications.

Post time: Oct-20-2023