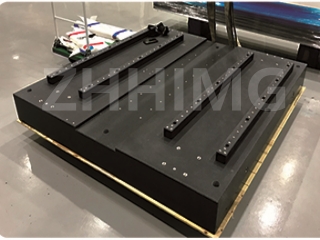

Granite machine bases are becoming more and more popular for applications in the precision machinery industry, particularly in the wafer processing industry. The benefits of using granite machine bases in wafer processing can be significant, mainly in terms of reduced vibration, increased stability, and improved accuracy.

Here are some ways to use granite machine bases effectively in wafer processing:

1. Choose the right base material

Granite machine bases are made from high-quality granite stone, which has excellent stability, thermal properties, and dampening characteristics. Machine builders need to choose the right granite material based on the specific requirements of their wafer processing application to ensure the best performance.

2. Optimize the machine design

Machine builders need to ensure that the machine design is optimized for the granite machine base they are using. This includes ensuring a proper weight distribution, reinforcing machine components like the columns, and ensuring that the machine is level.

3. Ensure adequate support

The granite machine base needs adequate support to function effectively. The machine builder needs to ensure that any support structure is rigid and robust to withstand the weight of the machine and the vibration produced during operation.

4. Reduce vibration

Vibration can be a significant problem in wafer processing, leading to reduced accuracy and repeatability. Granite machine bases have excellent dampening properties, reducing vibration to improve accuracy and repeatability.

5. Improve thermal stability

Granite machine bases have excellent thermal properties, ensuring that machines built on top of them remain stable regardless of temperature fluctuations. This is vital for wafer processing, where even small changes in temperature can affect accuracy.

6. Improve accuracy

The inherent stability of granite bases, along with reduced vibration and improved thermal stability, enables machines built upon them to achieve greater accuracy. This is essential in wafer processing, where precision is critical in every stage of production.

In conclusion, using granite machine bases in wafer processing offers significant benefits in terms of improved accuracy, stability, and reduced vibration. To use them effectively, machine builders need to choose the right base material, optimize the design, provide adequate support, reduce vibration, improve thermal stability, and improve accuracy. With these steps in place, granite machine bases can significantly improve wafer processing precision and accuracy, leading to higher-quality products and greater customer satisfaction.

Post time: Nov-07-2023