Granite machine parts are essential components used for cutting, shaping, and polishing granite or other natural stones. These parts help to reduce the intensity and duration of manual labour involved in stone-working processes, making the process faster, more efficient, and safer.

If you are looking to use granite machine parts, it’s important to understand the different components involved and how they work.

1. Diamond Blades

Diamond blades are one of the most common components of granite machine parts. These saw blades come with diamond particles on their cutting edges, which makes them more resistant to wear than traditional saw blades. Diamond blades come in various sizes and shapes and are used for different purposes. Some blades are designed to cut straight lines, while others can cut curves, intricate designs, and shapes.

2. Grinding and Polishing Pads

Grinding and polishing pads are used for grinding and polishing granite surfaces to make them smoother and shinier. These pads are made from abrasive materials such as diamond or silicon carbide, which help to remove the rough surfaces on the granite. They come in various grit sizes, and the coarser pads can be used for grinding, while the finer pads are used for polishing.

3. Water Jets

Water jets are an essential component of granite cutting machines. These jets use a high-pressure stream of water mixed with abrasive particles to cut through granite surfaces. Water jets are advantageous compared to traditional saw blades because they do not generate heat, which can damage the granite slab’s structure.

4. Router Bits

Router bits are used for cutting intricate designs and patterns on granite. These bits are diamond-tipped and come in various sizes and shapes. They are commonly used for creating bullnose edges, ogee edges, and other intricate designs.

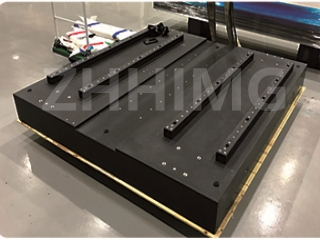

5. Bridge Saws

Bridge saws are heavy-duty machines used for cutting large granite slabs. These machines use diamond-tipped blades to cut through the granite with precision and speed. They are equipped with powerful motors and can cut through thick granite surfaces with ease.

Using granite machine parts requires proper knowledge of machinery and safety protocols. Always wear protective gear such as gloves, eye protection, and earplugs when using these machines. Make sure to follow the manufacturer’s instructions and guidelines when operating granite machine parts.

In conclusion, granite machine parts are essential components for cutting, shaping, and polishing granite or other natural stones. They make the process faster, more efficient, and safer while reducing manual labour intensity. By using these parts, you can achieve precise cuts, intricate designs, and smooth, polished surfaces on granite slabs.

Post time: Oct-17-2023