CNC equipment has revolutionized the world of manufacturing and processing with its advanced technology that offers precise and accurate operations. It is a crucial tool in various industries, including aerospace, automotive, and medical, among others. One of the essential components of CNC equipment is the bed, which serves as the foundation for the machine. While many materials are available to create CNC bed, granite has emerged as one of the most preferred options for many reasons.

Granite is a durable and robust natural material that offers excellent stability and rigidity for CNC equipment compared to other materials like cast iron or steel. Since granite is a natural material, it resists corrosion and degradation better than others. Additionally, it retains its accuracy and performance for a longer period, making it the ideal choice for long-term use.

Apart from its long-lasting strength, granite has also been recognized for its unique thermal properties. Granite has low thermal expansion, which allows it to maintain its dimensional stability, even at high temperatures. This means that the chances of thermal distortion or instability during operation are greatly reduced, which supports the machine's accuracy and precision. The heat absorption property of granite also helps to disperse the heat away from the machinery and reduces the chances of thermal variance.

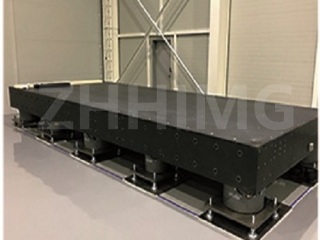

The CNC bed is essentially the foundation of the machine. Therefore, it is essential to consider the bed's vibration, rigidity, and stability when making it. With granite beds, you get all these features in large quantities, thanks to granite's great rigidity and vibration-dampening properties. Specifically, it has a high damping coefficient, which restricts vibrations and minimizes their impact on the machine.

Another significant advantage of granite beds is their accuracy and repeatability. Granite beds have a high degree of flatness and negligible curvature, making them ideal for milling, grinding, and drilling applications. The machine's performance depends on its ability to maintain its accuracy and repeatability. This is possible with granite beds due to the material's inherent stability, which supports precise and perfect operations.

In conclusion, granite beds offer a myriad of unique benefits to CNC equipment, including exceptional stability, rigidity, and thermal resistance, which translates to better accuracy and precision. The material's unique properties make it ideal for long-term use, thereby saving on costs and maintenance. Given the high-performance demands of CNC equipment, a granite bed provides the best foundation for machine stability, accuracy, and repeatability. Therefore, if you are looking for a high-quality bed for your CNC equipment, granite should be your first choice.

Post time: Mar-29-2024