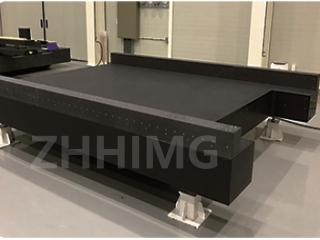

Granite bases are commonly used in semiconductor equipment due to their excellent stability, rigidity, and damping properties. These bases play a critical role in maintaining the precision and accuracy of the equipment, which ultimately contributes to the quality of the semiconductor products. Therefore, it is essential to ensure that these bases are well-maintained and meet the necessary requirements.

The following are some of the requirements for the maintenance and maintenance of granite bases in semiconductor equipment:

1. Regular Cleaning: Granite bases should be regularly cleaned to prevent the accumulation of dust, debris, and other contaminants. These substances can affect the accuracy of the equipment and cause damage to the surface of the granite. Cleaning should be done using a soft brush or a microfiber cloth and a mild detergent solution. Strong chemicals or abrasive cleaners should be avoided, as they can cause damage to the granite surface.

2. Lubrication: Granite bases require proper lubrication to prevent wear and tear and ensure smooth movement of the equipment. A suitable lubricant should be used, such as a high-quality silicone-based lubricant. The lubricant should be applied in small amounts and evenly distributed across the surface. Excess lubricant should be wiped off to prevent buildup.

3. Temperature Control: Granite bases are sensitive to changes in temperature, which can cause thermal expansion or contraction. The equipment should be kept in a temperature-controlled environment, and any changes in temperature should be gradual. Sudden changes in temperature can cause stress on the granite surface, leading to cracks or other damage.

4. Leveling: The granite base must be leveled to ensure the even distribution of weight across the surface. Uneven weight distribution can cause stress on the surface, resulting in damage over time. A level indicator should be used to check the level of the base regularly and adjust it as needed.

5. Inspection: Regular inspection of the granite base is essential to identify any signs of wear, damage, or defects. Any unusual or abnormal signs should be immediately addressed to prevent further damage or malfunction of the equipment.

In conclusion, maintaining and maintaining granite bases in semiconductor equipment is vital to ensure the accuracy, precision, and quality of the equipment and products. Regular cleaning, lubrication, temperature control, leveling, and inspection are some of the essential requirements that need to be followed to keep the granite bases in optimal condition. By adhering to these requirements, semiconductor companies can ensure the longevity and integrity of their equipment and products, ultimately contributing to their success and growth in the industry.

Post time: Mar-25-2024