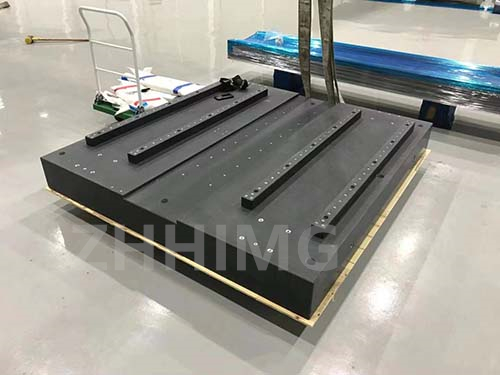

Granite components have become increasingly popular in the semiconductor industry as they offer a number of benefits over traditional materials. Granites are an ideal material for semiconductor equipment due to their unique physical and chemical properties. In this article, we will take a closer look at the design concept of granite components and how they are being used in the semiconductor industry.

Granite is a naturally occurring rock composed primarily of quartz, feldspar, and mica. It is known for its high density, good heat resistance, and high stiffness. These properties make it an ideal candidate for semiconductor equipment. Unlike metals, it has a minimal coefficient of thermal expansion, which means that its dimensions remain constant even with temperature changes. This makes it an ideal candidate for precision equipment where tight tolerances are crucial.

One of the significant advantages of granite components is its high stiffness, which enhances the equipment's accuracy. Granite components are preferred for precision equipment like metrology instruments and surface inspection equipment. Its stiffness reduces the vibration, thereby, giving better accuracy, repeatability, and precision in measurements. Granite enabled equipment to achieve a higher level of accuracy in measurement, thereby improving the quality of semiconductor components produced.

Granite's thermal stability makes it an ideal material for equipment exposed to high temperatures. Though many semiconductor components generate heat, they require low temperatures for optimal functioning. Granite components can withstand thermal fluctuations without changing shape or compromising the equipment's accuracy. As a result, the equipment produced using granite components is consistent and reliable.

Granite components are also corrosion-resistant, which is crucial in the semiconductor industry. Any corrosion of semiconductor equipment can lead to contamination of the resultant semiconductor components produced. This contamination can lead to a dip in quality, a decline in yields, and overall equipment malfunctions in the semiconductors. Granite components prevent corrosion and preserve the purity of the semiconductor equipment for a more durable and reliable performance.

Granite components also have high wear resistance, which means that the equipment produced with it can last longer and perform better, even under extreme conditions. With high longevity, it ensures efficiency in the semiconductor equipment, thereby enhancing productivity and reducing overall costs.

In conclusion, the semiconductor industry is rapidly growing and changing, and the use of granite components has gained market demand. Its unique properties have made it an ideal candidate for semiconductor manufacturers to produce equipment with excellent performance. The use of granite components has improved the overall quality yields of semiconductor equipment and enhanced performance, durability, and accuracy. Moreover, the semiconductor industry has benefited from the large-scale use of granite components with reduced repair costs, enhanced productivity, and reduced lead time. It is, therefore, an excellent move for semiconductor manufacturers to embrace granite components as a new and efficient material of choice for its equipment.

Post time: Mar-20-2024