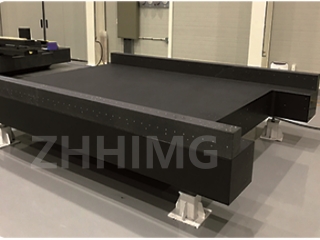

PCB drilling and milling machines are widely used in the electronics industry. One of the most commonly used materials for the machine's components is granite. Granite is a hard and durable material that can withstand high loads and operate at high speeds.

However, some concerns have been raised regarding the possibility of thermal stress or thermal fatigue occurring in the granite components of the PCB drilling and milling machine during high load or high-speed operation.

Thermal stress occurs when there is a difference in temperature between different parts of the material. It can cause the material to expand or contract, leading to deformation or cracking. Thermal fatigue occurs when the material undergoes repeated cycles of heating and cooling, causing it to weaken and eventually fail.

Despite these concerns, it is unlikely that the granite components of a PCB drilling and milling machine will experience thermal stress or thermal fatigue during normal operation. Granite is a natural material that has been used for centuries in construction and engineering, and it has proven to be a reliable and durable material.

Moreover, the design of the machine takes into account the potential for thermal stress or thermal fatigue. For example, the components are often coated with a protective layer to reduce the impact of temperature changes. The machine also has built-in cooling systems to regulate the temperature and prevent overheating.

In conclusion, the use of granite for the components of PCB drilling and milling machines is a proven and reliable option. While concerns have been raised about the potential for thermal stress or thermal fatigue, the design of the machine takes these factors into account and makes them unlikely to occur. The use of granite in PCB drilling and milling machines is a safe and effective choice for the electronics industry.

Post time: Mar-18-2024