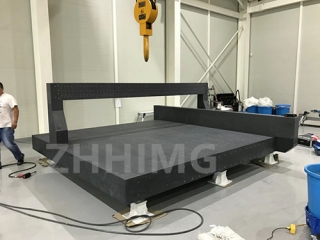

In the wave of the vigorous development of modern manufacturing industry, the machine tool as the "mother machine" of industrial production, its performance directly determines the processing accuracy and quality of the product. The machine tool base, as the core supporting part of the machine tool, plays a crucial role in the overall performance of the machine tool. Our company has been deeply engaged in the field of granite products for many years, carefully created granite precision components for the machine tool base has brought a revolutionary upgrade program, and is gradually becoming the first choice for many enterprises pursuing excellent processing accuracy.

Unmatched stability

In the process of high-speed operation and cutting, the machine tool will produce strong vibration and impact. The traditional metal base, affected by its own material characteristics, is difficult to effectively absorb and buffer these external forces, resulting in displacement and deformation during machine tool processing, which seriously affects the processing accuracy. Our granite precision components use natural high-quality granite as raw materials, its internal structure is dense and uniform, with high stability. After professional testing, the natural frequency of granite is much higher than that of metal materials, which can rapidly attenuate vibration. In practical application, the machine tool equipped with granite precision component base, in high-speed milling processing, the vibration amplitude can be reduced to less than 0.001mm, while the vibration amplitude of the ordinary metal base machine tool is 0.01mm-0.05mm, which greatly ensures that the tool and the workpiece always maintain accurate relative position. It achieves high precision machining at the micron or even nano level to meet the stringent requirements for parts processing accuracy in high-end manufacturing fields such as aerospace, precision electronics, and medical devices.

Excellent wear resistance

Machine tool base in the long-term use process, to withstand the frequent friction of machine tool components and cutting fluid erosion. The metal base is prone to wear, corrosion and other problems, which not only shortens the service life of the machine tool, but also leads to a gradual decline in processing accuracy as the wear intensifies. Our granite precision components rely on the high hardness characteristics of granite itself, with excellent wear resistance, its wear resistance is more than 5 times that of ordinary metal materials. In the actual production of an auto parts processing enterprise, the metal base machine tool is used, and the machining accuracy deviation caused by the wear of the base is more than ±0.05mm every year, which requires multiple maintenance and precision calibration; After replacing it with our granite precision component base, it has been used continuously for 5 years, and the processing accuracy deviation is still controlled within ±0.01mm, which greatly reduces the maintenance frequency and maintenance cost of the machine tool, and provides a solid guarantee for the long-term stable production of the enterprise.

Good thermal stability

The heat generated during the processing process will cause thermal deformation of the machine tool parts, which is another major problem affecting the machining accuracy of the machine tool. The thermal expansion coefficient of metal materials is large, and small temperature changes may lead to obvious dimensional changes, which seriously interferes with the machining accuracy. The thermal expansion coefficient of granite is extremely low, only 1/5-1/10 of metal materials. In the precision optical lens grinding workshop, when the ambient temperature fluctuates 5℃, the metal base grinding equipment is used, and the curvature accuracy deviation of the lens processing can reach ±0.005mm due to thermal deformation; The equipment equipped with our granite precision component base, under the same temperature change, the curvature accuracy deviation can be controlled within ±0.001mm, to ensure that the machine tool in the long-term continuous processing process, processing accuracy is consistent, greatly improving the consistency of production efficiency and product quality.

Personalized customization and perfect service

Our company has a professional R & D design team, which can provide personalized granite precision component customization services according to the structural characteristics, working loads and processing requirements of different types of machine tools. From the design of the product, the selection of raw materials, to the production and processing, quality testing, every link is strictly in accordance with the international advanced standards, to ensure that we can provide customers with the best quality products to meet their needs. At the same time, we have established a perfect pre-sale, sale, after-sales service system to provide customers with a full range of technical support and solutions. Before sales, professional staff to provide customers with detailed product consultation and selection suggestions; In the sale, follow up the order progress in time to ensure the timely delivery of products; After sales, rapid response to customer repair and maintenance needs, so that customers have no worries.

Choosing our granite precision components as the machine tool base is to choose higher processing accuracy, longer machine life, lower production costs and more intimate service. We sincerely invite the majority of machine tool manufacturing enterprises, machining manufacturers to cooperate with us to jointly explore the infinite possibilities of granite precision components in the field of machine tools, and open a new era of precision machining.

Post time: Mar-25-2025