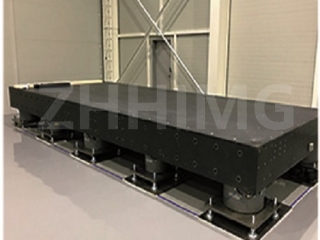

Precision Granite products have a vast range of application areas due to their exceptional hardness, stability, and corrosion resistance properties. These products are made from natural granite stone, which is known for its high density and durability. Granite is an igneous rock that is formed by the solidification of magma, and it is composed of several minerals, including quartz, feldspar, and mica. The natural properties of granite make it an ideal material for a wide range of applications, and Precision Granite products are widely used in different industries, including precision engineering, metrology, and scientific research.

The following are the application areas of Precision Granite products:

1. Precision Engineering

Precision Granite products are widely used in the precision engineering industry because of their high accuracy and stability. They are used as a base for machines and tools that require high accuracy and precision. Precision Granite products come in various shapes and sizes, making them ideal for different types of machinery and tools. These products are also used in the automotive industry for producing high-quality engine blocks, transmission housings, and other precision parts.

2. Metrology

Metrology is the science of measurement, and Precision Granite products are widely used in metrology applications due to their excellent stability and accuracy. These products are used as base plates for measuring instruments such as CMMs, height gauges, and other precision measuring tools. The high stability and accuracy of Precision Granite products make them an ideal material for metrology applications.

3. Scientific Research

Precision Granite products are also used in scientific research applications because of their stability and durability. Granite is a non-reactive material that does not corrode or rust, making it an ideal material for scientific research equipment. Precision Granite products are used in the production of various scientific instruments, including spectrometers, geology equipment, and microscopes. These products also have a low coefficient of expansion, which ensures the accuracy of the readings of scientific instruments.

4. Aerospace Industry

The aerospace industry requires highly precise and accurate machinery and equipment to produce safe and efficient aircraft. Precision Granite products are used in the aerospace industry to manufacture critical components such as jet engine parts, airframe components, and landing gear. The high accuracy and stability of Precision Granite products ensure the quality and reliability of the aircraft components.

5. Marine Industry

The marine industry requires materials that are resistant to corrosion and saltwater damage. Granite is a natural material that is highly resistant to corrosion and has excellent water resistance. Precision Granite products are used in the marine industry for producing boat engines, watercraft parts, and other marine equipment. The excellent durability and hardness of granite make it ideal for marine applications.

6. Machining Industry

The machining industry requires materials that are durable and can withstand high temperatures and pressures. Precision Granite products are used in the production of machining equipment, including milling machines, lathes, and other types of machine tools. The high stability and accuracy of Precision Granite products ensure the precision and accuracy of the machining process.

In conclusion, Precision Granite products are versatile materials that find applications in different industries. Their exceptional hardness, durability, and stability make them ideal for various industrial applications, including precision engineering, metrology, scientific research, aerospace, marine, and machining industries. The use of Precision Granite products in these industries ensures high accuracy, reliability, and durability of equipment and parts.

Post time: Oct-09-2023