In the frontier of precision manufacturing and scientific research, the demand for ultra-precision motion control is increasing day by day. As the key equipment to achieve high precision linear motion, the performance of the ultra-precision single-axis air floating module directly affects the quality of the final product and the accuracy of scientific research results. Among the many influencing factors, the application of granite base gives it an unparalleled advantage and becomes the core element to ensure excellent accuracy.

Granite, after millions of years of geological changes, the internal structure is extremely dense and uniform. It is mainly composed of quartz, feldspar and other minerals, this unique material composition gives granite excellent physical properties. When used as the base of a single axis air float ultra-precision motion module, granite first demonstrates extremely high stability. Compared with common metal material bases, granite bases show stronger deformation resistance in the face of external environmental disturbances, such as temperature fluctuations and mechanical vibration. In the process of electronic chip manufacturing, the positioning accuracy of chip lithography is required to reach nanometer level. In the production shop, the vibration generated by the operation of large equipment and the slight changes in the ambient temperature may affect the motion accuracy of the lithography equipment. The single axis air floating ultra-precision motion module with granite base can effectively attenuate external vibration and reduce the vibration amplitude transmitted to the motion module by more than 80%. At the same time, its extremely low coefficient of thermal expansion makes the size of the base change very little when the temperature changes, ensuring that the air floating motion module can still maintain stable motion accuracy in a complex environment, providing a precise positioning basis for chip lithography, and greatly improving the yield of chip manufacturing.

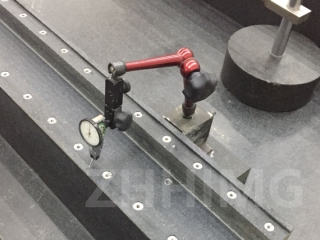

In addition, granite has good wear resistance. In the process of frequent reciprocating motion of the ultra-precision single-axis air float module, although there is a gas film support between the air float slider and the base, long-term use will inevitably produce a certain degree of friction. The granite base, with its high hardness characteristics, can effectively resist the wear caused by this friction and extend the service life of the motion module. In the scientific research laboratory of universities, the experimental equipment used for micro particle detection needs the ultra-precision motion module of uniaxial air flotation to run stably for a long time to obtain a large number of accurate experimental data. The high wear resistance of the granite base ensures that the accuracy of the motion module can still be maintained at the initial high precision level after a long time of use, providing a reliable guarantee for the continuity and accuracy of scientific research work, and helping researchers to deeply explore the mystery of the microscopic world.

The single axis air float ultra-precision motion module with granite base is like a precise "navigator" for precision manufacturing and scientific research. Granite base with its excellent stability, wear resistance, for the high-precision movement of the air floating motion module provides a solid support, in the semiconductor manufacturing, optical instrument manufacturing, high-end scientific research and many other precision requirements of the field, plays an irreplaceable important role, promoting the industry to higher precision, higher quality direction.

Post time: Apr-07-2025