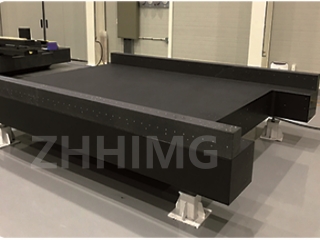

Granite has been a popular choice for a base in laser processing due to its excellent durability, stability, and vibration-resistance properties. In this article, we will explore the advantages and disadvantages of granite as a base material for laser processing.

Advantages of Granite

1. Durability: Granite is a natural igneous rock that has excellent durability against wear and tear, scratches, and other physical damage. This feature makes it a reliable and long-lasting base for laser processing machines.

2. Stability: Granite's stability is another essential advantage for laser processing, as it ensures the required level of precision in the machining process. The material is generally resistant to heat, chemical corrosion, and thermal expansion, making it a stable and reliable choice for the base of a laser processing machine.

3. Vibration-resistance: Granite is an excellent choice for laser processing due to its vibration-resistance properties. The vibrations caused by the laser machinery can cause errors and inaccuracies in the processing, but the granite base helps to dampen these vibrations and maintain the stability of the machinery.

4. Able to Absorb Thermal Energy: Granite has the ability to absorb thermal energy, which is another crucial feature in laser processing. When the laser processes a material, it generates a considerable amount of heat, which can cause the material to expand and contract. If the base is unable to absorb this thermal energy, it can cause inaccuracy in the process. The ability of granite to absorb this thermal energy helps to ensure the accuracy of the laser processing.

5. Aesthetically Appealing: Lastly, granite is a beautiful material that can give a sophisticated and elegant look to a laser processing machine. This feature can help improve the appearance of the machine and provide a positive impression to clients and visitors.

Disadvantages of Granite

1. Non-malleability: Granite is a naturally occurring and rigid material and cannot be molded or bent into custom shapes. This trait means that it may not be compatible with all types of laser processing machines and may have to be modified according to the specific requirements of the machine.

2. Heavy: Granite is a dense and heavy material that is challenging to transport and install. The installation of a granite base requires a specialized team and equipment for its safe and efficient placement.

3. Cost: Granite is a relatively expensive material that can increase the cost of the overall machine. The cost may, however, be reasonable, considering the improved quality, accuracy, and durability of the processing machine.

Conclusion

In conclusion, the advantages of granite as a base material in laser processing outweigh the disadvantages. The durability, stability, and vibration-resistance properties of granite provide accurate and precise processing while minimizing errors and inaccuracies. Granite can absorb thermal energy, ensuring the necessary level of accuracy and is aesthetically pleasing. Although the cost of granite may be higher than other materials, it is still a worthwhile investment due to its long-lasting properties.

Post time: Nov-10-2023