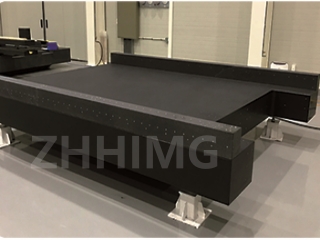

Granite is a naturally occurring igneous rock that is composed of a mixture of minerals, including quartz, mica, and feldspar. It has long been used in the manufacturing industry for its durability, resistance to wear and tear, and its ability to maintain its shape and dimensional stability over time. In recent years, granite bases have become increasingly popular for precision assembly devices due to their high level of stability and stiffness. In this article, we will explore the advantages and disadvantages of using granite bases for precision assembly devices.

Advantages of Using Granite Bases for Precision Assembly Devices:

1. High Stability and Stiffness: Granite has a high level of structural stability and stiffness, which provides an ideal base for precision assembly devices. The rigidity of granite helps to reduce vibrations and minimize the impact of external forces on the assembly process, resulting in better quality and accuracy.

2. Resistance to Wear and Tear: Granite is a highly durable material that can withstand the wear and tear of constant use. It does not deform easily, making it a reliable material for long term use.

3. Low Thermal Expansion: Granite has a very low coefficient of thermal expansion, which means that it has very little change in size due to temperature fluctuations. This feature makes it ideal for applications where precision and accuracy are critical, particularly in the production of microelectronics and medical devices.

4. Low Magnetic Susceptibility: Granite has a low magnetic susceptibility, which makes it ideal for precision assembly devices in magnetic fields. It does not interfere with magnetic sensors, and it does not produce a magnetic field of its own.

5. Easy to Clean: Stone is non-porous and resistant to staining, making it easier to maintain and clean. This is an important feature for environments that require a high level of cleanliness, such as medical device manufacturing.

Disadvantages of Using Granite Bases for Precision Assembly Devices:

1. Relatively Heavy: Granite is a dense material, which means it can be relatively heavy compared to other materials used for industrial applications. This can make it more difficult to move and transport the assembly device.

2. High Cost: Granite is a premium material that can be expensive compared to other materials used in industrial applications. However, its durability and long lifespan may justify the initial cost.

3. Difficult to Work with: Granite is a very hard material and can be difficult to machine. This can make it more difficult to create custom shapes and designs for precision assembly devices.

4. Susceptible to Cracks: Granite is a brittle material that can crack if subjected to a sudden impact or vibration. However, this risk can be mitigated through proper handling and maintenance.

In conclusion, the advantages of using granite bases for precision assembly devices greatly outweigh the disadvantages. Its high stability and stiffness, resistance to wear and tear, low thermal expansion, low magnetic susceptibility, and ease of cleaning make it an ideal material for precision assembly devices. While it may be relatively heavy, expensive, difficult to work with, and susceptible to cracks, these issues can be addressed through proper maintenance and handling. Overall, granite is an excellent choice for precision assembly devices that require a high level of accuracy and precision

Post time: Nov-21-2023