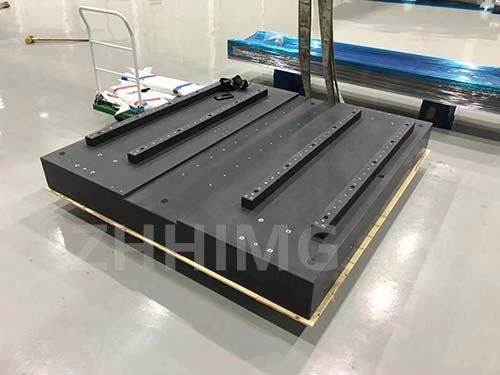

Automation technology refers to the use of machines and computers to perform tasks that would otherwise be done manually. These machines are made up of various parts, some of which can be made of granite. Granite is a type of igneous rock that is extremely hard and durable, making it an excellent material for machine parts. In this article, we will discuss the advantages and disadvantages of granite machine parts for automation technology.

Advantages of Granite Machine Parts

1. Durability: One of the main advantages of granite machine parts is their durability. Granite is an extremely hard and durable material, which makes it ideal for use in machine parts that undergo constant wear and tear. Machines made with granite parts can operate for extended periods without any significant damage or wear.

2. Resistance to wear and tear: Granite is a material that is highly resistant to wear and tear. It can withstand high levels of pressure, temperature, and vibration without any damage. This makes it an excellent choice for machine parts that have to endure constant use, such as bearings, gears, and other mechanical parts.

3. High precision machining: Granite is also an excellent material for high precision machining. The uniformity of the material makes it possible to produce very precise machine parts that have tight tolerances. This is particularly important in automation technology, where precision is critical for the proper functioning of machines.

4. Corrosion resistance: Granite is highly resistant to corrosion, which makes it an ideal material for machinery that comes into contact with corrosive materials like acids and alkalis. This property also makes it suitable for use in industries that require high levels of hygiene, such as food processing and pharmaceuticals.

Disadvantages of Granite Machine Parts

1. High cost: The main disadvantage of granite machine parts is their high cost. Granite is an expensive material, and the cost of manufacturing machine parts from it can be significantly higher than other materials like steel or aluminum.

2. Difficult to machine: Granite is a hard and abrasive material, which makes it difficult to machine. This can make the manufacturing process more challenging and time-consuming, which can lead to higher production costs.

3. Heavy weight: Granite is a dense material, and machine parts made from it can be heavy. This can be a disadvantage in certain applications where lighter machine parts are required to reduce the weight of the overall machine.

Conclusion

In conclusion, granite machine parts have many advantages that make them a suitable material for automation technology. Their durability, resistance to wear and tear, high precision machining, and corrosion resistance make them an excellent choice for machine parts that have to endure constant use and harsh environments. However, the high cost, difficulty in machining, and heavy weight of granite can be a disadvantage in certain applications. Overall, the advantages of granite machine parts outweigh the disadvantages, and they are an excellent choice for automation technology in many industries.

Post time: Jan-08-2024