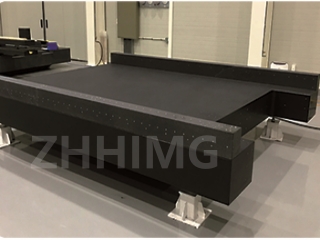

Granite is a common material used in the manufacturing of precision processing devices and tools. It is known for its exceptional durability, stability and precision. In this article, we will explore the many advantages that granite base provides for precision processing device products.

1. Hardness and Durability

One of the biggest advantages of granite base for precision processing devices is its extreme hardness and durability. Granite is a natural material that is formed over millions of years under high pressure and temperature. It is much harder than steel, which makes it ideal for applications that require high precision and accuracy. It can withstand a lot of wear and tear, and its surface is scratch-resistant. This means that the device will perform more reliably over time, saving downtime and maintenance costs.

2. Stability and Flatness

Granite is also known for its extreme stability, which is crucial in precision processing devices. The material does not easily bend, warp, or distort, which means that the devices built on it retain their precise dimensions and can maintain their accuracy over time. This stability also helps to reduce vibrations and improve accuracy. Its flatness makes it ideal for applications such as microscopy and precision measurement.

3. Non-Magnetic Properties

Another advantage of granite base is that it is non-magnetic, which means that it does not interfere with the magnetic fields that are often used for precision devices. Some materials can be sensitive to even small magnetic fields, which can be a significant issue for accuracy. By using granite, we can eliminate this risk and ensure that the device operates effectively and consistently.

4. Easy Maintenance

Granite base requires little maintenance, which is another advantage for precision processing devices. It is easy to clean and maintain, and its surface is resistant to most chemicals and solvents. This means that the device will remain in good condition and continue to perform at a high level for many years.

5. Cost-Effective Solution

Finally, using a granite base can be a cost-effective solution for precision processing devices. While it may be more expensive than other materials at the outset, it can save money on maintenance, downtime and replacement of parts over time. This is especially true for high-end devices, where the accuracy and reliability are critical to the success of the application.

Conclusion

In conclusion, using a granite base for precision processing devices offers many advantages. Its hardness, durability, stability, non-magnetic properties, and easy maintenance make it an ideal material for high-precision applications. Additionally, the cost-effectiveness of using granite makes it a smart choice for manufacturers and end-users alike. By choosing a granite base for precision processing devices, we can be confident that the device will perform reliably and maintain its accuracy over time.

Post time: Nov-27-2023