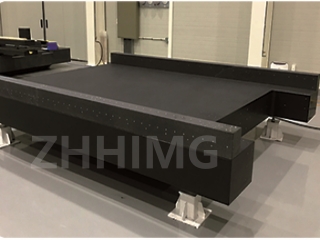

Granite is a natural stone that is known for its durability, strength, and resistance to wear and tear. Because of these properties, it is an ideal material for use in production equipment for the semiconductor industry, such as wafer processing equipment. In this article, we will explore the many advantages that granite offers in the context of wafer processing equipment production.

First and foremost, granite has a very low coefficient of thermal expansion. This means that it does not expand or contract significantly in response to changes in temperature. This is a particularly important property for wafer processing equipment, which must maintain precise tolerances to avoid damaging the delicate wafers being processed. If the equipment were made from a material with a higher coefficient of thermal expansion, then even minor changes in temperature could cause the equipment to expand or contract, leading to inaccuracies in the processing of the wafers.

Another advantage of granite is its high level of stability. It is an incredibly dense and hard material that is not easily worn down or eroded over time. This means that the equipment made from granite can be used for many years without needing to be replaced or repaired, even with heavy use. In addition, granite has exceptionally high dimensional stability, which means that it can maintain its shape and size over time despite changes in temperature or humidity.

Granite is also highly resistant to chemical corrosion, making it an ideal material for use in the harsh chemical environments common in wafer processing. Many of the chemicals used in wafer processing can be highly corrosive to metals and other materials, leading to damage or even failure of the equipment. Granite, however, is largely impervious to these chemicals, allowing it to function effectively and maintain its structural integrity over time.

In addition to these functional characteristics, granite has a number of other advantages when used in wafer processing equipment. It has a very attractive appearance, with a distinctive grain pattern that is both aesthetically pleasing and unique. This can be a valuable consideration for high-end semiconductor production facilities where appearances are important. Moreover, granite is a natural material that is sustainable and environmentally friendly, making it an attractive option for companies that prioritize sustainability.

In conclusion, the advantages of using granite in wafer processing equipment production are numerous and significant. From its low coefficient of thermal expansion to its high levels of stability and resistance to chemical corrosion, granite offers a unique set of characteristics that make it an ideal material for this industry. As such, it is a preferred choice for many semiconductor manufacturers around the world, and it is likely to remain so for the foreseeable future.

Post time: Dec-27-2023