Granite machine bases have become increasingly popular in recent years due to their inherent advantages over traditional materials like cast iron and steel. In the field of automation technology, granite machine bases offer several benefits that make them the preferred choice for many manufacturing operations. This article will discuss some of the primary advantages of granite machine bases and explain why they are the ideal material for automation technology products.

First and foremost, granite machine bases offer unmatched stability and vibration damping. This is important in automation technology, where precision and accuracy are critical for the success of the operation. Granite is a far superior material to cast iron or steel when it comes to damping vibrations, as it has a much lower natural frequency. This means that even small vibrations are absorbed and do not interfere with the operation of the machinery. With a granite machine base, manufacturing processes can run more smoothly, accurately, and efficiently.

Another advantage of a granite machine base is its resistance to thermal expansion. Traditional materials like cast iron and steel have a high coefficient of thermal expansion, meaning they change shape and size as they are exposed to changes in temperature. This can cause misalignment and other issues that can affect the accuracy and precision of the machinery. Granite, on the other hand, has a very low coefficient of thermal expansion, making it much more stable and reliable. This is particularly important in automation technology, where temperature changes can disrupt the operation of the machinery.

Granite machine bases also offer excellent rigidity and durability, which makes them ideal for automation technology products that require constant use. They are resistant to wear and tear, and they maintain their shape and surface finish even after years of heavy use. This translates to lower maintenance costs and longer equipment lifetimes, which is a significant advantage for any manufacturing operation.

Another advantage of granite machine bases is their superior dimensional stability. Unlike cast iron or steel, which can warp or deform over time, granite maintains its shape and dimensional stability even under extreme conditions. This is particularly important in automation technology, where precise tolerances are essential to the success of the operation. With a granite machine base, manufacturers can be confident that their equipment will maintain its accuracy and consistency over time.

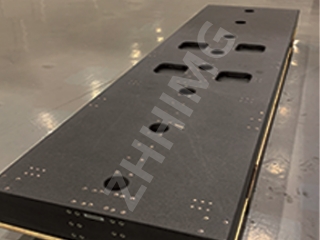

Finally, granite machine bases offer an attractive and modern appearance that can enhance the overall aesthetic of the manufacturing floor. They are typically finished to a high gloss, which gives them a sleek and professional appearance. This can be an important consideration for businesses that want to project a modern, cutting-edge image to their clients and partners.

In conclusion, granite machine bases offer several significant advantages over traditional materials like cast iron and steel. Their superior stability, vibration damping, resistance to thermal expansion, rigidity, durability, dimensional stability, and appearance make them the ideal choice for automation technology products. Whether you are designing a new manufacturing process or looking to upgrade your existing equipment, a granite machine base is an investment that will pay off in improved accuracy, precision, and reliability.

Post time: Jan-03-2024