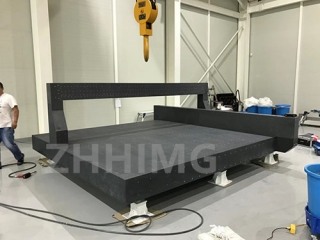

Granite machine bed is widely used in Wafer Processing Equipment products due to its excellent properties. Granite is a naturally occurring igneous rock that is known for its high durability, hardness, and resistance to wear and tear. As a result, granite has found extensive use in the manufacturing industry as a material for machine beds in various applications, especially those that require a high level of precision and stability. The following are some of the application areas of granite machine bed for Wafer Processing Equipment products:

1. Semiconductor Manufacturing

Semiconductor manufacturing is one of the most critical and complex processes in the electronics industry. The production of high-quality wafers requires the use of ultra-precise equipment that is capable of achieving tolerances of less than one micron. Therefore, granite machine beds are used in Wafer Processing Equipment products to ensure that the machines maintain their accuracy, stability, and repeatability over extended periods of use. Moreover, granite machine beds can absorb the vibrations generated during the manufacturing process, reducing the risk of damage to the delicate wafers and other components.

2. Optics manufacturing

Optical manufacturing is another application area for granite machine beds in Wafer Processing Equipment products. Granite machine beds are used in the production of high-precision optical components, such as lenses, prisms, mirrors, and filters, which require a high level of stability and accuracy during the manufacturing process. Granite machine beds can provide the necessary stability and rigidity to the machines, preventing any unwanted movement that could affect the final product's quality. Moreover, granite machine beds have a low coefficient of thermal expansion, which makes them suitable for use in temperature-controlled environments.

3. Medical Equipment Manufacturing

Medical equipment manufacturing is a highly specialized field that requires precision and accuracy in the production of various components, such as implants, prosthetics, and surgical instruments. Granite machine beds are used in Wafer Processing Equipment products during the manufacturing of medical equipment, ensuring that the machines can maintain their accuracy and repeatability over time. Moreover, granite machine beds are easy to clean, making it easier to maintain the cleanliness and sterility required in medical device manufacturing.

4. Aerospace and Defense

The aerospace and defense industries are two of the most demanding applications of Wafer Processing Equipment products. These industries require the production of components that can withstand extreme temperatures, pressure, shock, and vibration. Granite machine beds are used in these industries to provide a stable and rigid platform for the machines that manufacture critical components, such as missile guidance systems, jet engines, and satellite components. Moreover, granite machine beds are capable of withstanding extreme environmental conditions and have excellent shock resistance properties, making them an ideal choice for aerospace and defense applications.

In conclusion, Wafer Processing Equipment products play a crucial role in the manufacturing of various components in different industries. Granite machine beds are essential components of Wafer Processing Equipment products, providing the necessary stability, accuracy, and reliability required for high-precision applications. With their excellent properties, granite machine beds have become a popular choice for applications in semiconductor manufacturing, optics manufacturing, medical equipment manufacturing, and aerospace and defense.

Post time: Dec-29-2023