Granite is a type of natural stone that is widely used in various applications due to its unique features and properties. Its durability, resistance to wear and tear, and resistance to chemicals make it an ideal material for the production of high-precision equipment. One such application of granite is for LCD panel inspection device products. In this article, we will discuss the various application areas of granite based LCD panel inspection devices.

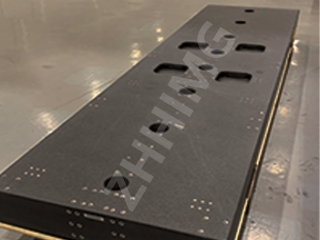

LCD panel inspection devices are used to check the quality and consistency of the LCD screens that are used in various electronic devices. These devices are used in the manufacturing process to ensure that each screen meets certain standards and specifications. The devices consist of various components that work together to inspect the LCD screens. One of the most important components in these devices is the base, which is made of granite.

The use of granite as a base material for LCD panel inspection devices has several advantages. First, granite is a very stable material that does not expand or contract due to changes in temperature or humidity. This makes it an ideal material for high-precision equipment, as it ensures that the device maintains its accuracy and precision over time. Secondly, granite is a very hard material that resists wear and tear, which means that the base of the device will last for a long time without requiring replacement. Lastly, granite is a non-magnetic material, which means it won't interfere with any electronic or magnetic signals during the manufacturing process.

One of the primary application areas of granite-based LCD panel inspection devices is in the manufacturing of electronic devices such as smartphones and tablets. These devices require high-quality LCD screens that are consistent and reliable. The use of granite-based inspection devices ensures that each screen meets the required standards and specifications, which helps to improve the overall quality of the product.

Another application area of granite-based LCD panel inspection devices is in the manufacturing of medical devices such as X-ray machines and ultrasound scanners. These devices require high-precision LCD screens that must be inspected and tested for accuracy and consistency. The use of granite-based inspection devices ensures that each screen meets the required specifications, which helps to improve the accuracy and reliability of the medical device.

In addition to the manufacturing industry, granite-based LCD panel inspection devices are also used in research and development labs. These devices are used to test new LCD screens and technologies to ensure that they meet the required standards and specifications. The use of granite-based inspection devices ensures that the results of these tests are accurate and reliable, which helps to improve the quality of future products.

In conclusion, granite-based LCD panel inspection devices have numerous application areas in various industries. The use of granite as a base material for these devices ensures that they are accurate, reliable, and durable, which helps to improve the overall quality of the products produced using these devices. Whether it's in the manufacturing of electronic devices, medical equipment, or in research and development, granite-based inspection devices play a critical role in ensuring that LCD screens meet the required standards and specifications.

Post time: Nov-01-2023