In the production of Coordinate Measuring Machines (CMM), granite is commonly used for its stability, durability, and accuracy. When it comes to producing granite components for CMMs, two approaches can be taken: customization and standardization. Both methods have their advantages and disadvantages that must be taken into account for optimal production.

Customization refers to the creation of unique pieces based on specific requirements. It may involve the cutting, polishing, and shaping of granite components to fit a particular CMM design. One of the significant advantages of customizing granite components is that it allows for more flexible and tailored CMM designs that can meet specific requirements. Customization can also be an excellent choice when manufacturing a prototype CMM to validate product design and functionality.

Another advantage of customization is that it can accommodate specific customer preferences, such as color, texture, and size. Superior aesthetics can be achieved through the artful combination of different stone colors and patterns to enhance the overall appearance and appeal of the CMM.

However, there are also some disadvantages to customizing granite components. The first and most significant is the production time. Since customization requires a lot of precision measuring, cutting, and shaping, it takes longer to complete than standardized granite components. Customization also requires a higher level of expertise, which may limit its availability. Additionally, customization can be more expensive than standardization because of its unique design and additional labor cost.

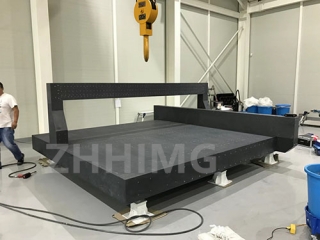

Standardization, on the other hand, refers to the production of granite components in standard sizes and shapes that can be used in any CMM model. It involves the use of precise CNC machines and fabrication methodologies to produce high-quality granite components at a lower cost. Since standardization does not require unique designs or customization, it can be completed much faster, and the production cost is lower. This approach helps to reduce overall production time and can also affect shipping and handling times.

Standardization can also result in better component consistency and quality. Since standardized granite components are produced from a single source, they can be duplicated with reliable accuracy. Standardization also allows for easier maintenance and repair since parts are more easily interchangeable.

However, standardization has its disadvantages as well. It may limit design flexibility, and it may not always meet specific design requirements. It may also result in limited aesthetic appeal, such as uniformity in stone color and texture. Additionally, the standardization process may result in some loss of precision when compared to customized components produced by more detailed craftsmanship techniques.

In conclusion, both customization and standardization of granite components have their advantages and disadvantages when it comes to CMM production. Customization provides tailored designs, flexibility, and superior aesthetics but comes with higher costs and longer production times. Standardization provides consistent quality, speed, and lower production costs but limits design flexibility and aesthetic variety. Ultimately, it is up to the CMM manufacturer and end-user to determine which method best suits their production needs and unique specifications.

Post time: Apr-11-2024