Granite is a commonly used material in precision measuring equipment due to its many advantages. Its unique properties make it ideal for ensuring accuracy and reliability in a variety of industrial and laboratory applications.

One of the main advantages of granite in precision measuring equipment is its exceptional stability and rigidity. Granite has a low coefficient of thermal expansion, which means it is less likely to expand or contract with changes in temperature. This stability ensures that the dimensions of the measuring device remain consistent even under fluctuating environmental conditions, which is crucial for accurate measurements.

In addition, granite has excellent damping properties, which means that it absorbs vibrations and minimizes the impact of external disturbances on measuring equipment. This is especially important in precision applications, as even the slightest vibration or movement can affect the accuracy of the measurement. The inherent damping properties of granite help maintain a stable and controlled environment for accurate measurements.

Additionally, granite is known for its high hardness and wear resistance. This makes it extremely durable and able to withstand heavy use without degrading or deforming over time. Granite's hardness also contributes to its ability to maintain a flat and smooth surface finish, which is critical for the efficient operation of precision measuring equipment.

In addition to its mechanical properties, granite is resistant to corrosion and chemical damage, making it suitable for use in a variety of industrial and laboratory environments requiring exposure to harsh substances.

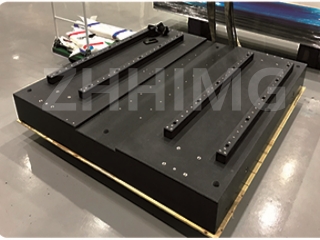

Natural stability, damping properties, durability and resistance to environmental factors make granite an excellent choice for precision measuring equipment. Its use in applications such as coordinate measuring machines, stages and optical comparators has proven its reliability and effectiveness in ensuring accurate and consistent measurements.

In summary, granite’s advantages in precision measuring equipment make it the material of choice for industries that require high precision and reliability. Its unique combination of properties makes it an integral component in the design and manufacture of precision measuring instruments, helping to improve the quality and accuracy of a variety of manufacturing and scientific processes.

Post time: May-22-2024