Precision granite components are essential tools in the manufacturing, inspection, and metrology industries. They provide a flat, stable, and accurate surface from which measurements can be taken. Granite is an ideal material for precision components because of its stability, density, and low coefficient of thermal expansion.

There are different types of precision granite components that are used in various applications, depending on their specifications and requirements. Some of the most common types of precision granite components are:

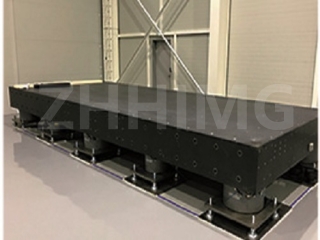

1. Surface Plates – Surface plates are large, flat plates made from granite. They typically come in sizes ranging from a few inches to several feet in length and width. They are used as a reference surface for the inspection, testing, and measurement of various tools and parts. Surface plates may have different grades of accuracy, ranging from Grade A, which is the highest, to Grade C, which is the lowest.

2. Granite Squares – Granite squares are precision milling and inspection tools that are used to check the squareness of parts, as well as to set up milling machines and surface grinders. They come in various sizes, ranging from a small 2x2-inch square to a larger 6x6-inch square.

3. Granite Parallels – Granite parallels are precision blocks that are used to align workpieces on milling machines, lathes, and grinders. They are available in various lengths and widths, with the height being the same for all the blocks in a set.

4. Granite V-Blocks – Granite V-blocks are used to hold cylindrical-shaped workpieces for drilling or grinding. The V-shaped groove on the blocks helps to center the workpiece for accurate machining.

5. Granite Angle Plates – Granite angle plates are precision tools that are used for layout, inspection, and machining of parts. They are typically manufactured to strict specifications, with angles ranging from 0 to 90 degrees.

6. Granite Riser Blocks – Granite riser blocks are used to increase the height of surface plates, angle plates, and other precision tools. They are used to raise workpieces to a comfortable height for inspection and machining.

In addition to the different types of precision granite components, there are also different specifications and grades that are used to determine their accuracy and quality. The accuracy of a precision granite component is typically measured in microns, which is a unit of measurement that is equivalent to one thousandth of a millimeter.

The grade of a precision granite component refers to its level of accuracy. There are several grades of precision granite components, with Grade A being the highest and Grade C being the lowest. The grade of a precision granite component is determined by its flatness, parallelism and surface finish.

In conclusion, precision granite components are essential tools for the manufacturing, inspection, and metrology industries. There are different types of precision granite components that are used for various applications, and they come in different specifications and grades to ensure that they meet the accuracy, stability, and quality requirements of the industry.

Post time: Feb-23-2024