In the design and construction of linear motor platform, the effective integration of granite precision base and feedback control system is the key to ensure the high precision and high stability of the whole system. There are several considerations involved in this integration process, several of which are important in detail below.

First, material selection: the advantages of granite

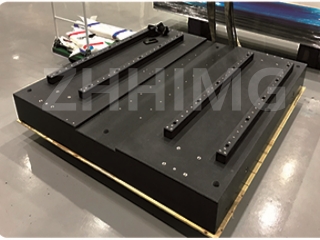

Granite is the preferred material for the linear motor platform base, and its excellent physical and chemical properties provide a solid foundation for the system. First of all, the high hardness and wear resistance of granite ensure the durability of the base and can withstand long-term, high-intensity operation. Secondly, its excellent chemical resistance enables the base to resist the erosion of various chemicals, ensuring that the system can operate stably in a variety of environments. In addition, the thermal expansion coefficient of granite is small and the shape is stable, which is of great significance to ensure the accuracy and stability of the system.

2. Selection and design of feedback control system

The feedback control system is an indispensable part of the linear motor platform. It monitors the running state of the system in real time and adjusts the motor movement through the control algorithm to achieve accurate control of the target position. There are several key factors to consider when selecting and designing a feedback control system:

1. Accuracy requirements: According to the specific application requirements of the linear motor platform, determine the accuracy requirements of the feedback control system. This includes position accuracy, velocity accuracy and acceleration accuracy.

2. Real-time: The feedback control system needs to be able to monitor the operating status of the system in real time and respond quickly. Therefore, when selecting a control system, it is necessary to consider its performance indicators such as sampling frequency, processing speed and response time.

3. Stability: The stability of the feedback control system is crucial to the operation of the entire system. It is necessary to select a control system with stable control algorithm and good robustness to ensure that the system can run stably under various conditions.

Third, integration of granite base and feedback control system

When integrating the granite base with the feedback control system, the following aspects need to be considered:

1. Accuracy matching: Ensure that the machining accuracy of the granite base matches the accuracy requirements of the feedback control system. This can be achieved by precisely measuring and calibrating the size and position of the base.

2. Interface design: A reasonable interface is designed to connect the granite base with the feedback control system. This includes electrical interfaces, mechanical interfaces and signal interfaces. The interface design should take into account the scalability and maintainability of the system.

3. Debugging and optimization: After the completion of integration, the entire system needs to be debugged and optimized. This includes adjusting the parameters of the control system, testing the performance of the system and making the necessary calibration and correction. Through debugging and optimization, we can ensure that the system can reach the expected performance index in actual operation.

To sum up, the integration of granite precision base and feedback control system in linear motor platform needs to consider multiple factors. By selecting suitable materials, designing reasonable control system and effective integrated debugging, the high precision and high stability of the whole system can be ensured.

Post time: Jul-25-2024