Granite components are an essential part of semiconductor equipment that is used in the manufacturing process of microchips and integrated circuits. These components are made from high-grade natural stone that has been engineered to meet the specific requirements of the semiconductor industry. Granite is a popular choice for semiconductor manufacturing equipment due to its outstanding strength, stiffness, and thermal stability. In this article, we will explore the main functions of granite components in semiconductor equipment.

1. Vibration Damping

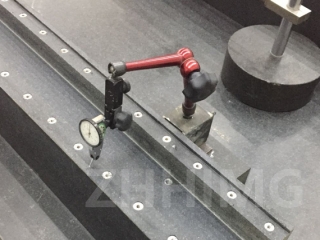

One of the primary functions of granite components in semiconductor equipment is to provide vibration damping. Microchip manufacturing requires a clean and stable environment, and vibrations can cause contamination and disrupt the manufacturing process. Granite components are used in critical areas of semiconductor equipment, such as wafer chucks and stages, to absorb and dampen vibrations caused by the equipment's movement or external factors.

2. Thermal Stability

Granite components are known for their excellent thermal stability. The semiconductor manufacturing process requires high temperatures, and the equipment must maintain a stable temperature to avoid errors or malfunctions. Granite components have a low coefficient of thermal expansion, which means they do not expand or contract significantly with temperature variations. This feature enables the equipment to maintain a stable temperature and minimize temperature gradients.

3. Dimensional Stability

Another critical function of granite components is the dimensional stability they provide. The manufacturing process requires precision and accuracy, and the equipment must maintain its precise dimensions throughout the process. Granite components have high rigidity and low thermal expansion, which means they are less prone to deformation caused by temperature changes or external forces. This feature ensures that the equipment maintains its precise dimensions during the manufacturing process.

4. Chemical Resistance

Granite components are chemically inert and resistant to many chemicals commonly used in the semiconductor industry. Chemical resistance is essential because the manufacturing process involves the use of various chemicals such as acids, bases, and solvents that can damage the equipment. Granite components can withstand exposure to these chemicals, reducing the risk of damage to the equipment and ensuring the manufacturing process runs smoothly.

5. Cleanliness

Granite components are easy to clean and maintain. They have a smooth surface that makes them easy to wipe clean and does not harbor bacteria or other contaminants, making them ideal for use in cleanroom environments. Cleanliness is essential in the semiconductor manufacturing process to prevent contamination of the microchips and ensure consistent quality.

Conclusion

Granite components play a critical role in semiconductor equipment and contribute to the precision and accuracy required in the manufacturing process. These components provide vibration damping, thermal and dimensional stability, chemical resistance, and cleanliness, which are vital to the efficient and effective operation of the equipment. As technology advances, the demand for high-quality semiconductor equipment will continue to increase, and granite components will remain an essential part of this equipment.

Post time: Apr-08-2024