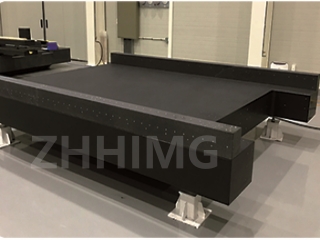

Industrial computed tomography (CT) is a non-destructive testing technique that uses X-rays to generate a three-dimensional digital image of an object. The technique is widely used in various industries such as aerospace, automotive, and medical. One of the crucial components of an industrial CT system is the granite base. In this article, we will discuss the requirements of granite base for industrial CT products on the working environment and how to maintain the working environment.

Requirements of Granite Base for Industrial Computed Tomography Product

1. Stability: Granite base for industrial CT products should be stable and free from vibrations. Stability is essential as it ensures accurate results in CT scanning. Any vibration or movement in the granite base can cause distortion in the CT image.

2. Thermal stability: Industrial CT systems generate a significant amount of heat during operation. Thus the granite base for industrial CT products should possess thermal stability to withstand the temperature changes and maintain its shape over time.

3. Flatness: The granite base should have a high degree of flatness. Any deformations or irregularities in the surface can cause errors in CT scanning.

4. Rigidity: The granite base should be rigid enough to withstand the weight of the CT scanner and the objects being scanned. It should also be able to absorb any shock or vibration caused by the movement of the scanner.

5. Durability: Industrial CT systems can run for several hours a day. Thus the granite base should be durable and able to withstand long-term use and abuse.

6. Easy maintenance: The granite base should be easy to clean and maintain.

How to Maintain the Working Environment

1. Regular cleaning: The granite base should be cleaned on a regular basis to remove dust and debris, which can affect the accuracy of CT scanning.

2. Temperature control: The working environment should be maintained at a constant temperature to ensure thermal stability of the granite base.

3. Vibration control: The working environment should be free from vibrations to prevent distortion in CT images.

4. Protection from external forces: The granite base should be protected from external forces such as impacts or shock, which can damage the surface and affect the accuracy of CT scanning.

5. Use of anti-vibration pads: Anti-vibration pads can be used to absorb any shock or vibration caused by the movement of the CT scanner.

In conclusion, granite base is a crucial component of an industrial CT system. It helps to ensure stability, rigidity, durability, and flatness of the CT scanner's working surface. Maintaining the working environment is crucial for increasing the longevity of the granite base and for ensuring accuracy in CT scanning.

Post time: Dec-08-2023