Granite mechanical components are commonly used in precision processing devices due to their high stability, stiffness, and low thermal coefficient of expansion. However, these components have specific requirements for the working environment to maintain their effectiveness and ensure that they do not degrade over time. In this article, we will consider the requirements of granite mechanical components for precision processing device products in the working environment and how to maintain the working environment.

1. Temperature

Granite mechanical components are sensitive to temperature changes. The optimal operating temperature for granite components is 20-25°C. If the temperature is too high or too low, it can cause changes in the dimensions of granite components. Therefore, it is necessary to ensure a constant temperature in the working environment through air conditioning or heating systems. The temperature should be maintained within the range of 18-26°C to ensure accurate and stable measurements.

2. Humidity

Granite components are also sensitive to moisture and humidity. High humidity levels can cause corrosion and wear, which can affect the accuracy of measurements. Therefore, the working environment should be maintained at a humidity level of 40-60%. This can be achieved by using dehumidifiers or by ensuring proper ventilation.

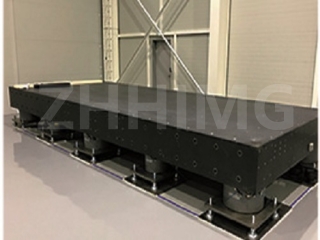

3. Vibrations

Vibrations can cause granite components to wear out and lose their accuracy. Hence, it is essential to avoid sources of vibration in the working environment. This can be achieved by isolating the machine or equipment on which the components are mounted from the surrounding environment. It is also recommended to use shock-absorbing materials to minimize the effects of vibrations.

4. Dust and debris

Granite components are susceptible to dust and debris. Dust and debris can cause wear and tear, leading to errors in measurements and accuracy. Therefore, it is necessary to maintain a clean working area free from dust and debris. This can be achieved through regular cleaning and wiping of the working area.

5. Maintenance

Regular maintenance of granite components is essential to ensure their longevity and accuracy. The components should be inspected regularly for wear and tear. Any signs of wear and tear should be rectified immediately. Also, regular calibration of the equipment should be done to ensure accuracy.

In conclusion, granite mechanical components play a vital role in precision processing device products. To ensure that these components function optimally, it is necessary to maintain a controlled and clean working environment. Maintaining a constant temperature, humidity, and avoiding vibrations are essential for accurate measurements. Dust and debris should be kept at a minimum, and regular maintenance of the components is necessary. By following these guidelines, the life-span of granite components will be prolonged, and the precision processing device products will remain accurate and reliable.

Post time: Nov-25-2023