Granite Precision Components: Factors to Consider When Integrating into a VMM Machine

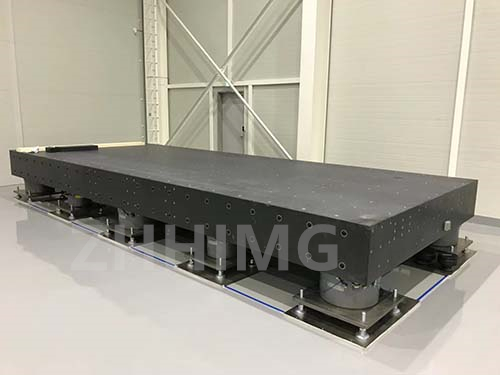

When it comes to integrating granite precision components into a VMM (Vision Measuring Machine) machine, several factors need to be carefully considered to ensure optimal performance and accuracy. Granite is a popular choice for precision components due to its excellent dimensional stability, high rigidity, and resistance to wear and corrosion. However, to fully leverage the benefits of granite in a VMM machine, the following factors should be taken into account:

1. Material Quality: The quality of the granite used for precision components is crucial. High-quality granite with uniform density and minimal internal stress is essential for achieving precise and reliable measurements in a VMM machine.

2. Thermal Stability: Granite's thermal stability is a key consideration, as temperature fluctuations can affect the dimensional accuracy of the components. It is important to select granite with low thermal expansion properties to minimize the impact of temperature variations on the machine's performance.

3. Rigidity and Damping Characteristics: The rigidity and damping properties of the granite components play a significant role in minimizing vibrations and ensuring stable measurements. Integrating granite with high rigidity and excellent damping characteristics can enhance the overall accuracy and repeatability of the VMM machine.

4. Surface Finish and Flatness: The surface finish and flatness of the granite components are critical for achieving precise measurements. Careful attention should be given to the manufacturing processes to ensure that the granite surfaces are smooth, flat, and free from imperfections that could compromise the accuracy of the VMM machine.

5. Mounting and Alignment: Proper mounting and alignment of the granite precision components within the VMM machine are essential for maintaining the integrity of the measurements. Precision mounting techniques and meticulous alignment procedures should be employed to ensure that the granite components function seamlessly within the machine.

6. Environmental Considerations: The operating environment of the VMM machine should be taken into consideration when integrating granite precision components. Factors such as temperature control, humidity levels, and exposure to contaminants should be managed to preserve the dimensional stability and performance of the granite components.

In conclusion, integrating granite precision components into a VMM machine requires careful attention to material quality, thermal stability, rigidity, surface finish, mounting, alignment, and environmental factors. By addressing these considerations, manufacturers can optimize the performance and accuracy of their VMM machines, ultimately enhancing the quality and reliability of their measurement processes.

Post time: Jul-02-2024