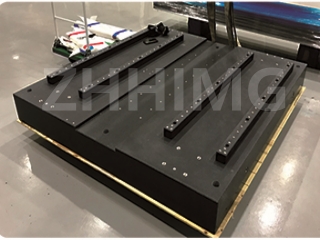

Granite assembly is an important component in semiconductor manufacturing process devices. It is a key support structure that provides a stable and flat surface for the intricate manufacturing processes involved in the semiconductor industry. Granite has unique properties that make it an ideal choice for use in semiconductor manufacturing.

Firstly, granite is a very hard and durable material. It is resistant to scratches, wear and tear, and chemical corrosion. This means that it is an ideal material for use in semiconductor manufacturing processes, as it does not react with the chemicals and acids used in the manufacturing process, which can damage other types of materials.

Secondly, granite has excellent thermal stability. This means that it is able to maintain its shape and dimensional stability even when subjected to high temperatures. This is important in semiconductor manufacturing processes, where high temperatures are often used to melt and fuse materials together. Without thermal stability, components could warp or change shape, leading to defects in the final product.

Thirdly, granite has exceptional dimensional stability, which allows it to maintain its shape and size over time. This is important in semiconductor manufacturing processes where precision and accuracy are critical. Without dimensional stability, manufacturing processes could be inaccurate and lead to defective products.

Granite assembly is used as a platform for semiconductor manufacturing. It provides an extremely flat and stable surface that enables the precise manufacturing of the tiny, intricate circuits required in semiconductor devices. Granite assembly platforms are also used as a basis for camera systems that are used to inspect the surface of the semiconductor wafers during production.

Overall, granite assembly for semiconductor manufacturing processes is an important component that provides a stable and flat surface for intricate and precise manufacturing processes. Its unique properties of hardness, thermal and dimensional stability make it an ideal choice for use in the semiconductor industry. With its use, the semiconductor industry can continue to produce precise and high-quality semiconductor devices that power today's technological advancements.

Post time: Dec-06-2023