Granite precision components: the cornerstone of industrial precision manufacturing

In the field of precision manufacturing in modern industry, granite precision components have become the core elements in many high-precision applications with their unique charm and excellent performance. As a naturally formed hard stone, granite not only has excellent physical properties, but also shows extraordinary precision and stability with the blessing of precision machining technology.

The uniqueness of granite precision components

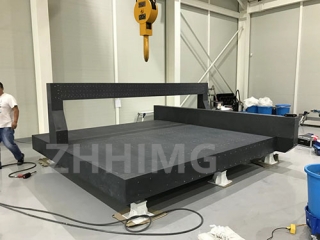

Granite precision components, in short, is the use of high-quality granite through high-precision machining and fine grinding made of parts. They not only inherit the natural advantages of granite itself, such as hardness, wear resistance and corrosion resistance, but also bring these characteristics to the extreme through precision manufacturing technology. Every detail of these components has been carefully designed and polished to ensure that they exhibit the best stability and accuracy during use.

The wide range of application fields

Granite precision components play an important role in many industrial fields. In the field of machining, they are often used as the base and guide rail of high-precision machine tools to provide stable support and accurate guidance for the machining process. In the field of optics and measurement, granite precision components are ideal for high-precision measurement equipment and optical instruments due to their low coefficient of thermal expansion and high stability. In addition, in high-tech fields such as aerospace and semiconductor manufacturing, granite precision components also play an irreplaceable role.

The rigor of the technical requirements

In order to ensure the performance and quality of granite precision components, the manufacturing process must follow strict technical requirements. From the selection of raw materials to the control of the processing process to the final quality inspection, every link needs to be carefully operated and strictly checked. For example, in the selection of raw materials, we must choose high-quality granite with uniform texture, no cracks and defects; In the process of machining, it is necessary to use advanced CNC machining equipment and fine grinding technology to ensure that the geometric accuracy and surface roughness of the component meet the design requirements; In terms of quality inspection, it is necessary to use high-precision measuring equipment and strict testing standards to ensure that every component meets the quality requirements.

Look to the future

With the continuous progress of science and technology and the continuous improvement of industrial manufacturing level, the application prospect of granite precision components will be broader. With the continuous emergence of new materials and the continuous innovation of processing technology, the performance and quality of granite precision components will continue to improve. At the same time, with the increasing awareness of environmental protection, people's requirements for green manufacturing and sustainable development are getting higher and higher. Therefore, in the future, the manufacturing of granite precision components will pay more attention to environmental protection and sustainability to meet the market demand for green products.

In short, granite precision components, as the cornerstone of industrial precision manufacturing, will continue to play an important role in the future. We look forward to the promotion of science and technology and industry, granite precision components can show more excellent performance and more extensive application prospects

Post time: Jul-31-2024