Granite vs. Marble: The Performance of Precision Components in Harsh Environments

When it comes to precision components used in harsh environments, the choice of material can significantly impact performance and longevity. Granite and marble are two popular choices for precision components, each with its own set of characteristics and advantages. In terms of wear and corrosion resistance, precision granite components have proven to be highly effective, making them a preferred choice for applications in demanding conditions.

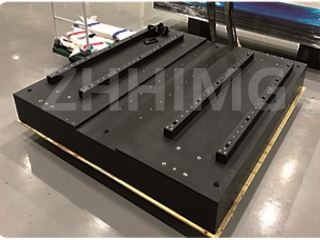

Granite is a natural stone known for its exceptional durability and resistance to wear and corrosion. Precision components made from granite exhibit excellent performance in harsh environments, maintaining their structural integrity and functionality over extended periods. The inherent hardness and density of granite make it highly resistant to abrasion and chemical corrosion, ensuring reliable performance in challenging industrial settings.

In comparison, marble precision components may not offer the same level of wear and corrosion resistance as granite. While marble is prized for its elegance and aesthetic appeal, it is a softer and more porous material than granite, making it susceptible to wear and chemical damage over time. In harsh environments where exposure to abrasive materials, moisture, and corrosive substances is prevalent, granite precision components are generally considered more suitable for long-term use.

In industrial applications such as heavy machinery, manufacturing equipment, and precision instruments, the superior wear and corrosion resistance of granite components make them an ideal choice for ensuring reliable performance and longevity. The robust nature of granite allows for minimal maintenance and upkeep, reducing downtime and operational costs associated with component replacement and repair.

In conclusion, when evaluating the performance of precision components in harsh environments, granite emerges as the preferred material in terms of wear and corrosion resistance. Its exceptional durability and resistance to environmental stressors make it a reliable choice for long-term use in demanding industrial settings. While marble may offer aesthetic appeal, its limitations in terms of durability and resistance make it less suitable for prolonged exposure to harsh conditions. Ultimately, the choice between granite and marble precision components should be based on the specific requirements of the application and the need for reliable, long-lasting performance in challenging environments.

Post time: Sep-06-2024