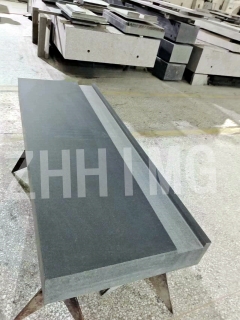

CNC (computer numerical control) machine tools are used in various industries such as manufacturing, aerospace, automotive, and many more. These machines are used to cut, shape, and carve materials like metal, plastic, wood, and granite. CNC machines require a sturdy base to provide them with stability and preciseness, which is why granite base is used as a critical component in CNC machine tools.

Granite is known for its excellent dimensional stability and resistance to deformation, making it a perfect material to use in the construction of machine tool bases. The stability of granite ensures that the movement of the machine during the cutting operations does not affect the accuracy of the cuts. The high hardness and uniform structure of granite ensure low distortion and high stability even under extreme temperatures and pressure.

The use of granite as a base also provides a high level of damping to CNC machines. The natural shock-absorbing properties of granite allow machines to operate at high speeds without jerking or sudden stops, improving precision and accuracy. The vibrations caused by the cutting process can cause unwanted movement in the machine, but due to the damping characteristics of the granite, these vibrations are minimized or eliminated altogether.

Moreover, granite base makes CNC machine tools have an accurate and level working surface. Granite has very low roughness and high flatness, which means that the surface of the granite is flat to within a few microns. When the machine bed is properly installed on top of the granite base, it allows for the machine to have a stable and accurate working surface. This ensures that the machine tool cuts to the exact specifications required.

Another advantage of using granite in the base of CNC machines is that it provides excellent resistance to chemicals and corrosion. Granite is resistant to most acids, bases, and solvents, making it an ideal material to use in harsh environments. This is crucial in industries where chemicals and oils are commonly used, as it reduces the likelihood of rust and contamination on the machine tool's surface.

In conclusion, the granite base is an essential component in CNC machine tools. It ensures the stability of the machine during the cutting process, reduces vibrations, provides a level working surface, and improves precision and accuracy. The benefits of using granite as a machine base make it popular in various manufacturing industries and allow machine tools to operate at high levels of efficiency and accuracy.

Post time: Mar-26-2024