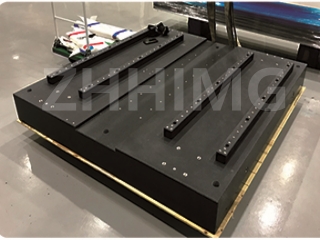

Granite is a natural stone that has various aesthetic and practical applications, including its use in the production of Coordinate Measuring Machines (CMM). CMMs are high-precision measuring instruments that are designed to determine the geometry and dimensions of an object. They are used in various industries, including aerospace, automotive, mechanical engineering, and more.

The importance of accuracy in CMM measurement cannot be overstated, as a difference of even a few thousandths of an inch can make the difference between a product that works and one that is flawed. Therefore, the material used to construct the CMM must be able to maintain its shape and remain stable over time to ensure accurate and consistent measurements. Moreover, the material used must also be able to withstand harsh operating conditions.

In this article, we will discuss why granite is an ideal material for CMM construction, and what properties make it perfect for the job.

1. Stability:

One of the most important properties of granite is its stability. Granite is a dense and inert material that is highly resistant to deformation and does not expand or contract with temperature changes. As a result, granite components offer excellent dimensional stability, which is essential for achieving high accuracy levels in CMM measurements.

2. Excellent vibration damping:

Granite has a unique structure that gives it excellent vibration damping properties. It can absorb vibrations and isolate them from the measuring platform to achieve stable measurement results. Effective vibration control is crucial for ensuring quality CMM measurements, particularly in noisy environments. The vibration damping properties of granite allow it to filter out unwanted interference and ensure reliable results.

3. Wear resistance:

Granite is a highly durable material that can withstand the wear and tear that comes with continuous use in industrial environments. It is resistant to scratching, chipping, and corrosion, making it an ideal material for CMM components that come into contact with moving parts and abrasive agents.

4. Thermal stability:

Granite has a low coefficient of thermal expansion, meaning it does not expand or contract significantly with temperature changes. As a result, it can maintain its shape, even when subjected to temperature fluctuations, allowing CMMs to produce accurate results over a wide range of operating temperatures.

5. Machinability:

Granite is a hard and challenging material to work with. It requires advanced technical expertise and specialized equipment to shape and finish it correctly. Nevertheless, its machinability allows for precise machining of granite components, resulting in high-quality finished products.

In conclusion, granite is an ideal material for CMM construction because of its superior stability, vibration damping properties, wear resistance, thermal stability, and machinability. Granite CMMs are built to withstand harsh operating conditions and provide high-precision measurements. Additionally, they offer a long service life, maintenance-free operation, and stability, making them a wise and cost-effective investment for a wide range of industries.

Post time: Apr-02-2024